Defective bearings in the transmission – causes and diagnostics

Although automatic transmissions are becoming increasingly popular in passenger cars, manual transmissions are still widely used in many types of vehicles. Their failure usually results from improper use or – in the case of repairing – the use of low-quality spare parts.

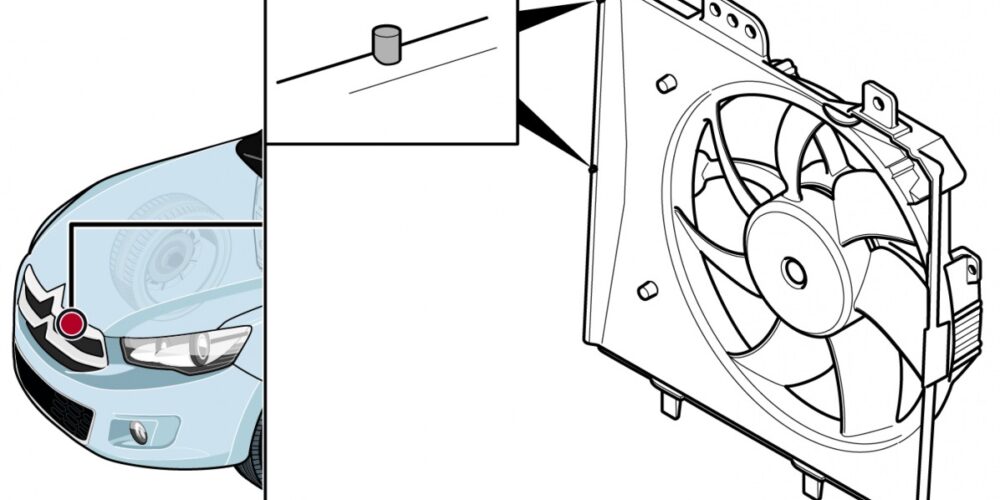

One of the most common faults in the transmission is the bearing wear. What are the reasons for such failures and how to conduct proper diagnostic procedures? The manual transmission is composed of shafts: the input shaft, the output shaft and – depending on the structure – the countershaft. The pinion mounted on the input shaft transmits the drive to the countershaft pinion. There are pairs of pinions on both shafts, corresponding to specific gears. These components are connected by synchro-mesh units. Selecting a particular gear causes the disconnection of the remaining pinions. Another important component in this entire puzzle is the bearing. In terms of front-wheel cars, the gear housing also contains a differential. Lubrication and cooling of the transmission are provided by transmission fluid.

There can be many reasons for excessive wear of the bearing. The fault usually results from long and regular journeys with maximum load and without monitoring the transmission fluid level. Many drivers still share a common belief that after the fluid has been poured into the transmission, either manual or automatic, it does not require a periodic inspection or sometimes even replacement, and its amount does not change during the vehicle use. In most cases, this is not true, and such negligence can lead to costly failures. The exceptions are, of course, transmissions with bearings which wear out prematurely due to design flaws.

If the gear is too noisy, but it makes the aforesaid sounds when one specific gear is selected, it is probably caused by a worn out pinion or a bearing adjacent to this pinion. If shifting gears is accompanied by screeching sounds or a difficulty occurs while shifting them, it can be a sign of damaged synchro-mesh units. The crucial moment is the early detection of faults and replacement of defective components as the transmission might suffer due to a snowball effect.