Why do American engines generate so little power from huge displacements?

It is no secret that American automotive is built around powerful engines. However, their strength lies not in power, but in displacement. There was a period in the history of overseas automotive where 5.5L engines were referred to as small blocks. So why, despite their huge displacement, are these engines not the most powerful units?

What is the trend of huge engines in the US?

In American automotives of the 90s, engines with a displacement of about four liters were as popular as two-liter units in Europe. There are many factors that have influenced this state of affairs, however, it is impossible to describe them all, so we will focus on the most important ones.

First of all, the source of this phenomenon should be sought in history. While Europe, devastated by war, was forced to spend huge amounts of money on reconstruction, and citizens were barely making ends meet, a golden age was beginning in the United States. The USA became a world producer of many goods due to the fact that factories in Europe were destroyed during the war. This resulted in high wages even for the lowest production workers who wanted to buy the largest cars with the biggest engines possible. When the world rebuilt its production capacity and production workers’ wages stopped increasing, their automotive preferences did not change and they still expected large vehicles.

Large engines maintained their popularity even later despite the fuel crisis and the gradual introduction of ecology. Taxes had a big influence on this. Namely, cars in the States are not subject to taxation based on engine displacement. In the USA, the tax is based on the car’s average range per gallon (3.79L) of fuel. Thanks to such legislation, manufacturers did not focus on building small engines with high power, but concentrated on reducing the amount of fuel consumed.

Big engines – small performance

The power of the mighty engines from across the ocean is often the subject of jokes among European automotive enthusiasts. After all, in the 90s, the European Ford Mondeo with its 2.0 DOHC engine generated 138 HP, which is 69 HP per liter, while one of the most popular Ford cars of the 90s in the USA, the Ford Explorer, with its 4-liter engine, generated only 160 HP, which gives a mere 40 HP per one liter of displacement. And what about consumption? According to the manufacturer, the Ford Mondeo consumed 8.1L per 100 km in a mixed cycle, while the Ford Explorer needed 13.2L to cover the same distance. So where are the advantages of powerful American engines hidden?

To get to the heart of it, attention should first be paid to the geographic aspect. The United States is a huge country where everything is far away. American cities do not have narrow and winding streets, and parking spaces are adapted to large machines. Therefore, local engineers did not have to develop small city cars, but focused on highway cruisers that can cover hundreds of miles at highway speeds with no problem. For this reason, the construction of these engines is also different from European or Asian units.

Outdated OHV – the king of reliability

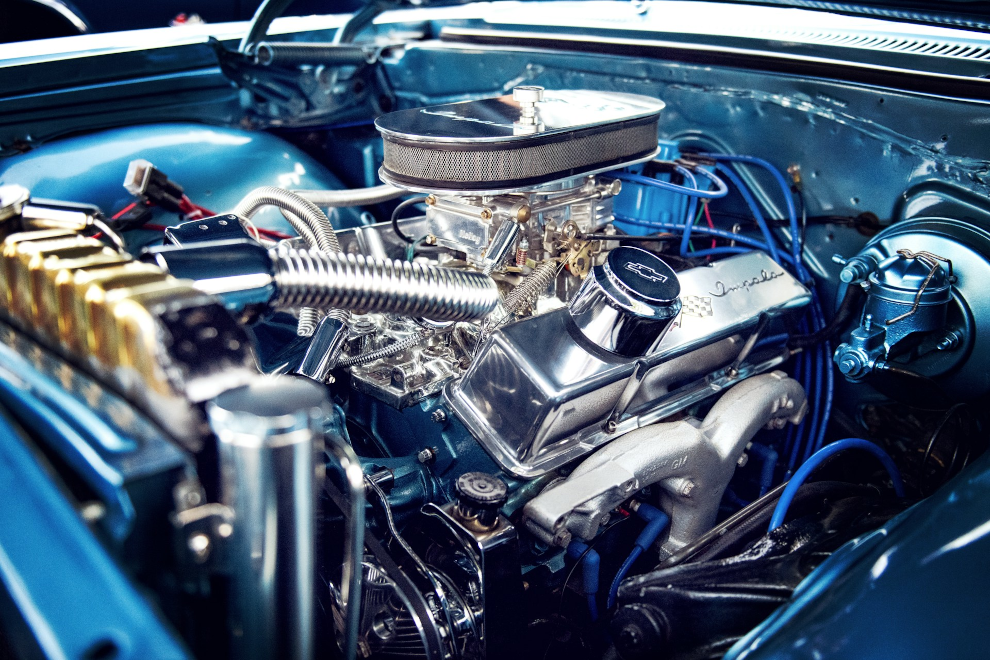

Overhead valve engines with the camshaft in the engine block, due to the strong focus on downsizing in Europe, have been replaced by engines with one or two overhead camshafts. In the United States, however, these engines are considered to be immortal units for special tasks and not only. Why?

Large engines with the camshaft in the block allow for high torque from the lowest RPMs, thanks to which highway cruisers were able to accelerate to highway speeds, and sports cars with a touch of the gas pedal would tear asphalt from under the wheels. What is very important is that almost the same engines were used in both types of vehicles. Even today, the F-150, a powerful Pick-Up from the Ford stable, shares engines with the sporty Ford Mustang. It is a way to reduce the costs of designing new engines and lower the market price of these cars. Using these engine constructions also brings benefits resulting from low maintenance and production costs. OHV engines have a much simpler timing system. As a result, they do not require expensive parts to be produced. Moreover, the simple construction of these engines minimizes repair costs, which due to this design occur less frequently than in engines with camshafts in the head.

Why do large OHV engines generate small power?

The answer to the question in the headline will hardly surprise anyone. The small power results from the use of such and not another timing system. Due to their design, the engines in cars from the USA have significantly lower maximum engine rpm. For example: the 6.2L engine from the 2008 Chevrolet Corvette has a maximum engine speed set at 6600 and generates 436 HP, while the 4.0 engine from the BMW M3 reaches up to 8400 rpm, generating a power of 414 HP. The reason for this situation is the higher mass of the timing system components. OHV engines have a heavy camshaft that is connected to the valves through pushrods and valve lifters, while engines with camshafts in the head have an almost direct connection with the valves.

The second reason for the lower power of such engines is the lack of the possibility of using variable valve timing technologies, which are commonly used in modern DOHC engines. Then there is also the issue of the number of valves per cylinder. Due to the design in OHV engines, four-valve systems are not used. This means that at higher engine speeds, they have an insufficient gas flow, which greatly limits their potential.

Another aspect affecting the power of American engines is the matter of symmetry in the combustion chamber, or rather the lack of it. The layout of two valves and a spark plug is dictated by the type of timing. The components arranged in this way carry the risk of knocking combustion at a higher compression ratio. Hence, power units from the USA have a lower compression ratio than engines from Europe or Asia. However, this is also their advantage. Engines with a lower compression ratio are less strained, which positively affects their longevity.

Using an analogy to the world of sports, one could say that European cars are sprinters, and American motoring relies on marathon runners. With the current development of technology, engine choice no longer relies on deciding which technology is better. Both have clear disadvantages and advantages. Currently, customers make choices based solely on their own beliefs and sympathies.