Introduction of fuel injection systems

Throughout the long history of internal combustion engines, there has been continuous research into how to mix gasoline and air in the most efficient way before ignition, so that it results in the highest power output and the most perfect combustion.

Although many car manufacturers have already stopped the development of gasoline engines, there should be no doubt that research in this direction is still taking place at many companies today, and it is also possible that we will see new, innovative solutions in the field in the future.

In this article, we present a brief historical overview of injection systems, as well as the advantages and disadvantages of using the main types.

Conditions of mixture formation

Although the moment came when the automotive industry switched from carburetors to electronic injection, the laws of physics remained unchanged. Injectors have given designers a lot of freedom, but there are some aspects that must be taken into account during design in all circumstances.

For example, wherever gasoline and air are mixed, before the moment of combustion, we must obtain a gaseous mixture, otherwise the combustion will be imperfect. This is especially critical for a direct injection system.

The mixing ratio is also such a property: the air-gasoline vapor mixture is flammable only in specific mixture ratios. The distribution of the mixture between the cylinders (depending on the system) or the problem of cold starting is also an influencing factor.

Low pressure, i.e. intake port injection

According to textbooks from a few decades ago, carefully designed and properly adjusted carburetors fulfill all the functions of the mixture formation process in engines, except for emissions. This sentence holds its place, but it is important to add that under the same conditions as modern injection systems, extra power can be extracted from the resource – we will come to this later.

After carburettors, external mixing systems were the first to appear in road applications in the Bosch-Daimler-Benz cooperation in the 1950s. The injection nozzles were placed in the space in front of the intake valve, in a similar way to today’s designs.

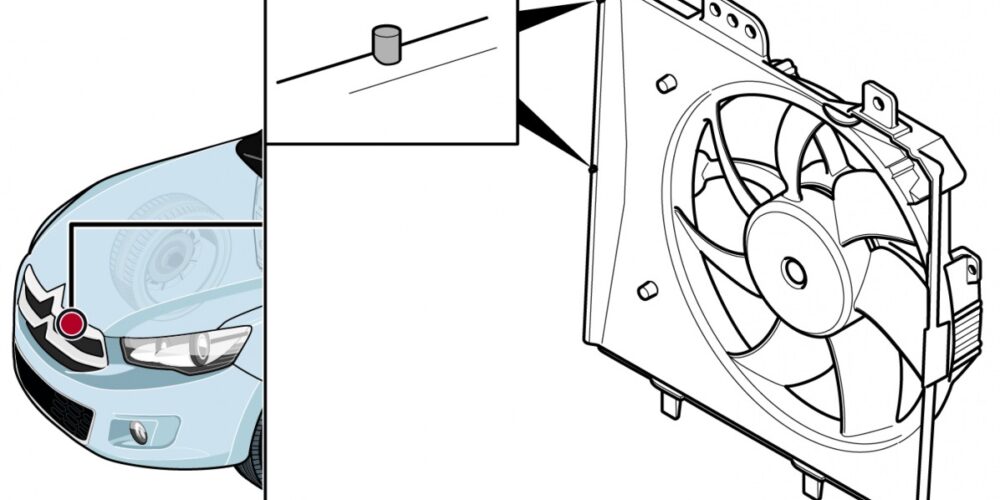

Sectional view of intake port injection (source: www.wikipedia.org)

Since the required injection pressure is low, the previously indispensable piston metering pumps have become unnecessary.

The first mechanical system with continuous injection was the Bosch K-Jetronic, and the first electric version was introduced by Bendix in 1957.

With intake pipe injection, there are two different options for delivering fuel into the intake chamber:

- Injection into a common suction throat: This is called single-point or mono-injection. In this case, we are talking about a central injection.

- Intake valve injection: This is per-cylinder injection, during which separate injectors per cylinder are placed near the intake valves.

One of the biggest advantages of intake port injection is that it is a very simple and cheap construction and does not require a high-performance pump. Since there is a relatively large amount of space available for the proper mixture of gasoline and air, the engine can be easily operated in the entire air ratio range.

In the case of injection on the intake valve, it is also considered an advantageous feature that part of the gasoline ends up on the wall of the valve chamber and on the valve plate, where it immediately evaporates, and this also helps to cool the parts at the same time.

High pressure direct injection

We might think that this version is considered more modern, but we cannot say that the idea is considered modern. Almost a hundred years ago, high-pressure injectors were used almost without exception in aircraft engines, and then it infiltrated the world of racing and sports cars as well. Even later, it appeared as the savior of two-stroke engines operating with high scavenging losses, where, in addition to its many technical advantages, the loss of the simplicity of two-stroke engines was an obstacle to its wider spread.

The real breakthrough was finally brought by the development of electronics and the increasing importance of emissions and specific fuel consumption. In order to achieve the latter, direct injection proved to be the most effective, as it enabled the use of incredibly lean mixtures with the help of layered mixture formation.

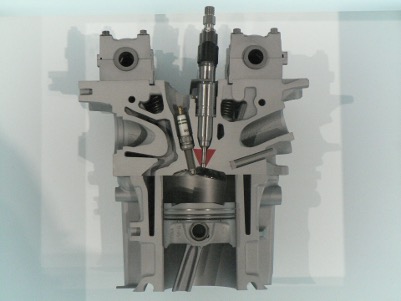

Cutaway model of direct injection (source: www.wikipedia.org)

We had to wait until the 1990s for the appearance of a larger number of series models equipped with this system.

A common feature of the system is that the injection valve is located in the cylinder head, right next to the intake valves. The finely atomized propellant goes directly into the combustion chamber. By properly coordinating the swirling of the fuel entering the combustion chamber and the air flowing into the gasoline, it is possible to create a stratified mixture. This means that the mixture in the combustion chamber will be purposefully inhomogeneous – a richer mixture is created around the spark plug, and a significantly leaner mixture further away.

This seems to be a contradiction based on previous knowledge, according to which the goal is to create a completely homogeneous mixture, but this way it is possible to use an extremely lean mixture (30-40:1) when the engine is partially loaded, which can be interpreted above a lambda value of two. This of course results in significant fuel savings.

It is important that this option only works at partial load. At full load, the engine switches to homogeneous mixture operation, in which case the injection takes place already in the intake stroke, with the intake valves open, essentially in a low-pressure space.

In this case, additional power is also available compared to intake pipe injection, its use in competitive sports is no accident. At partial load, however, the disadvantage is that due to the use of a very lean mixture, the nitrogen oxide concentration of the combustion products increases significantly, which must be treated afterwards. To solve the problem, on the one hand, the recirculation of the exhaust gases and, on the other hand, a specially designed second catalyst are used.

Combined injection

Since both systems have indisputable advantages, a significant number of today’s modern cars have both systems at the same time. The engine control electronics uses the services of one, the other, or even both injection systems depending on the operating state.

https://www.cars.com/articles/what-are-the-different-types-of-fuel-injection-1420690418419/

https://en.wikipedia.org/wiki/Fuel_injection

https://en.wikipedia.org/wiki/Fuel_injection#/media/File:PetrolDirectInjectionBMW.JPG

https://en.wikipedia.org/wiki/Fuel_injection#/media/File:Marvel_Fuel_Injection_System_Cross_Section.png