Upgrading the chassis technology

The vehicle industry just like any other development-oriented field, often comes up with innovative technology that can even radically change our previous knowledge of a topic.

The appearance of the air spring was a similar phenomenon. Although it is a fact that its origins go back more than a hundred years, it only started to spread in the 50s and since then it has become an inseparable part of the world of road vehicles.

In the article below, we present the history, construction and differences of the air spring compared to other springs.

Historical overview

The first relevant idea that can be connected to the air suspension chassis is connected to the British engineer, Archibald Sharp. In January 1901, he filed several patents, which were related to pneumatic suspension for bicycles.

The idea was followed by developments and in 1909, a company called Air Springs Ltd started the A.S.L. the production of a motorcycle, where the front and rear wheels sprung pneumatically. Due to many „childhood illnesses”, the project did not have a long life and in 1914 production was stopped.

Almost parallel to Sharp, on January 22 in 1901, the American William W. Humphreys patented an idea called the “pneumatic spring for vehicles”. However, it did not become a relevant product in the USA for a long time.

In America, the Second World War really brought the air spring to life. This old idea was brought up because in the case of airplanes, the suspension could be designed in a compact way and in the case of trucks, the height of the superstructure became independent of the current load – we will write about this in detail later.

After the Second World War, air-suspension chassis became widespread everywhere. Perhaps Mercedes came closest to the current versions in 1962, because at that time the Mercedes-Benz W112 platform already had air suspension on the 300SE models.

Toyota came even closer in 1986 with the Toyota Soarer, which introduced the first electronically controlled (TEMS), semi-active full air suspension (constant spring, variable damping force).

The air spring and the system behind it

An air spring is nothing more than a flexible air tank. Depending on the application, the bottom and top connections are the piston and the cover/flange plate. Their raw materials are very diverse, we can find everything on the market from various polyamide plastics to steel.

In the majority of cases, the two closing elements are attached to the rubber membrane which forms the elastic wall of the air spring by some pressing/cracking process.

The membrane itself is made up of several elements.

Depending on the vehicle in which it is used, a single air spring can contain many different layers of rubber film. The materials used are very diverse, there are many types of rubber from EPDM to neoprene.

It may seem obvious but the rubber membrane is not only made of rubber. We also find (usually at least 2) layers in which there are fabric fibers embedded in a rubber film. They are responsible for taking the load. The fabric fibers form an angle with the axis of the air spring, which determines its diameter at operating pressure.

The material of the fabric fibers is typically some kind of plastic (polyamide, aramid, etc.), so corrosion is not possible in the membrane.

Of course, this does not mean that the part is invulnerable. If the membrane is cracked or torn, the air spring becomes practically unusable and must be replaced.

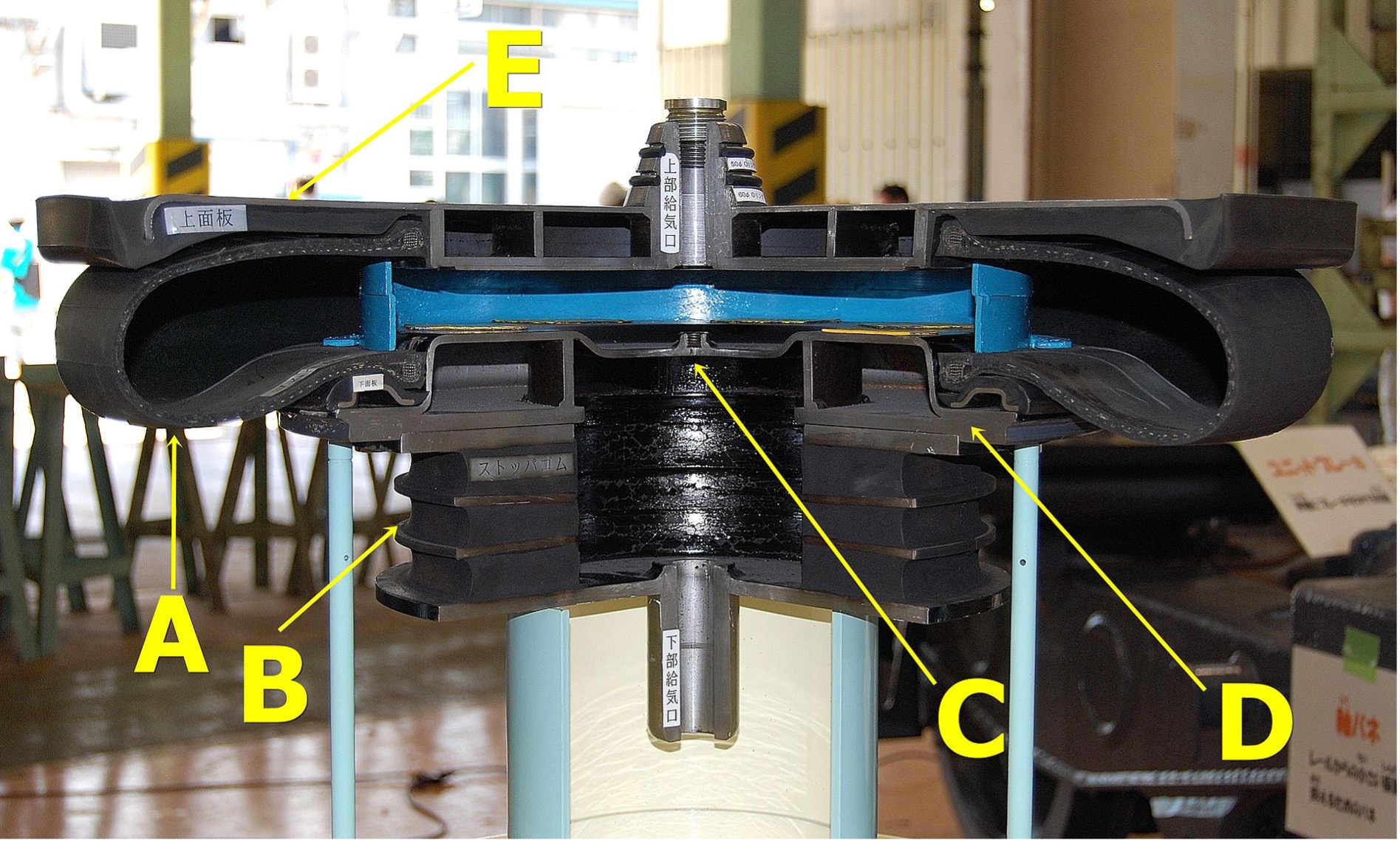

Sectional diagram of an annular air spring (“convoluted”) (source: www.lezo.hu)

We also distinguish some versions according to design: their characteristics may also differ.

The characteristic of the annular air spring is constant or depends only on the pressure of the air inside it. As it can be seen on the drawing, these air springs are connected by means of pipelines to structures that can change the amount and pressure of the air in the air spring, for example for the purpose of height adjustment.

Sectional diagram of a rolling lobe air spring (source: www.lezo.hu)

The role of the rubber canvas in the rolling membrane air spring is only sealing: in the case of a gasous medium, a piston ring cannot be used. At the same time, the design of the piston can influence the characteristics here as well: the cylindrical piston continues in a cone at the bottom and this gives the opportunity for the upward moving piston to have a larger “useful” surface (the rubber seal gradually smooths over the cone’s mantle).

There is an air spring whose medium is not only air.

Section of a truck air spring (source: www.wikipedia.org)

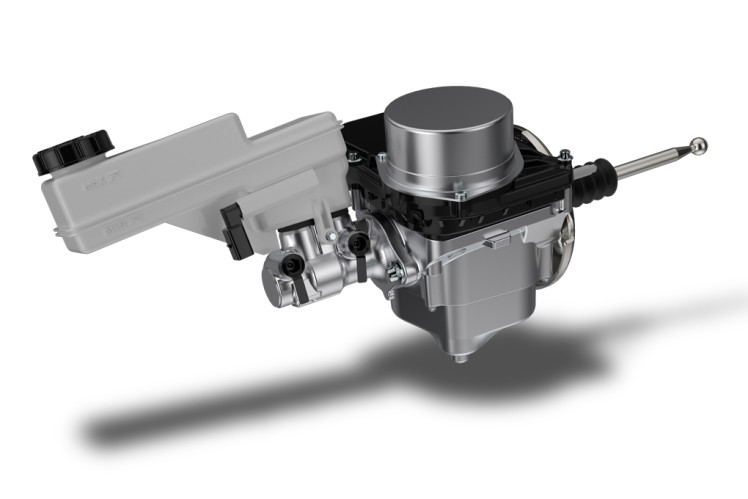

The hydropneumatic air spring consists of two main parts: a hydraulic cylinder and an air chamber sealed with a membrane which are connected by a wire. The “wire” is short if these two parts are built on top of each other. The advantage of the separate construction is that the working cylinder can easily be placed next to the wheel to be sprung due to its small size.

Finally, there is a progressive increase in force for compressing the air about the air spring in general, which is very favorable.

As for the practical design, it is important to mention that the air springs must be supplied with medium. The complete system is large, heavy and energy-intensive, as the system also includes a compressor, pressure storage, control electronics and piping too.

The weight and price of the system alone determine that the technology is viable only in the upper segments in the case of passenger car applications.

In the case of large commercial vehicles, this problem does not exist, especially with air brake systems, since the air supply is already ensured there.

Advantages-disadvantages, spread in passenger cars

The previous chapter already defined some disadvantages, such as the weight, the price – and here we must also mention the maintenance, because the replacement of air springs consumes unpleasant sums even in the case of passenger cars and destruction during use is almost guaranteed.

At the same time, let’s not forget about the benefits. As mentioned, air suspension systems are able to change the height of the superstructure by increasing the pressure, regardless of the load. This has tangible advantages in the case of commercial vehicles, but it cannot be neglected in the case of passenger cars that we can change the ground clearance of the vehicle as we please within a range.

In addition, air suspension chassis represents a different level of ride comfort than, for example, its counterparts with coil springs. Its characteristics cannot be imitated with traditional solutions and with intelligent control even body tilts/nods can be eliminated.