Bearings, creators of the possibility of movement

We rarely think that driving a car would be almost unthinkable without the existence of a component called bearing which has apparently negligible importance. This part has a huge importance in the existence of every other means of transport or machine where some kind of rotational movement takes place.

In this article, we present the structure and operation of bearings in a more general section and a section focusing on passenger cars.

Definition

A bearing is a machine component that limits relative motion to only the desired motion and reduces friction between moving parts. The design of the bearing can ensure, for example, free linear movement of the moving part or free rotation around a fixed axis or it can prevent motion by controlling the vectors of normal forces acting on moving parts.

Most bearings facilitate the desired movement by minimizing friction. Bearings are broadly classified according to the type of operation, the permitted movements or the direction of the loads (forces) applied to the components.

Slewing bearings support rotating components such as axles or shafts in mechanical systems and transmit axial and radial loads from the source of the load to the structure that supports it. The simpliest form of bearing, the plain bearing, consists of a shaft rotating in a bore.

Lubrication is used to reduce friction. To reduce sliding friction in ball and rolling element bearings, rolling elements such as rollers or balls with a circular cross-section are placed between the races or pins of the bearing assembly. A wide variety of bearing designs are available to meet the needs of the application for maximum efficiency, reliability, durability and performance.

Main types in cars

Plain bearing

There are many different types of bearings, so we will concentrate on the versions that are most common in road vehicles.

Bearings must be firstly distinguished according to their operating principle. One such principle is that the bearing is built in between the parts that rotate relative to each other and the moving part runs on a layer of lubricant, a so-called film, between the rotating and stationary parts.

This practically means that the two metals do not come into contact with each other when they are properly lubricated but there is a thin layer of oil between them.

Plain bearings with plastic coating (source: www.wikipedia.org)

The point of this is to minimize wear and tear. If there is no friction then there is no wear either and therefore the elements fitted together in this way do not wear out.

If the lubricant is no longer present, the amount of friction increases dramatically, along with significant wear and heat generation. Due to the amount of heat generated, the bearing material may melt and the joint may become tight.

For plain bearings, the matching of component materials is also very important. The material of the bearing must always be softer than the material of the connecting parts – these are the so-called lubricants – so not only the high heat caused by the same surface hardness but also in the case of a pinch, the cheaply replaceable bearing will be ruined, not the expensively replaceable part.

Plain bearings are found on the main shaft of the engine, where the support bearings and the bearings of the connecting rods also work on this principle.

Rolling element bearing

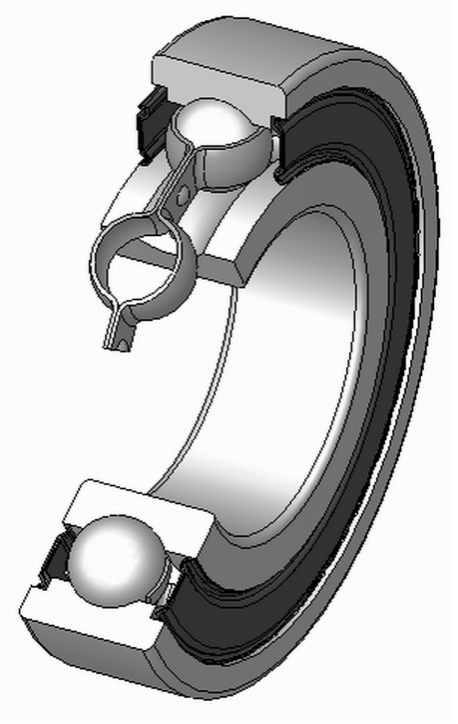

The essence of the principle is that the bearing consists of two rings, which can rotate on each other with rolling elements between them. Rolling elements can be balls or rollers.

In ball bearings, the balls run in a track inside the rings. This is the simplest, most common and also the cheapest rolling element bearing.

Structure of a ball bearing (source: www.wikipedia.org)

Rolling element bearings are most widely used in passenger cars but typically in all road vehicles. According to the types of roller elements, we also distinguish cylindrical roller, needle roller and barrel rolling element bearings.

In addition to the above, there are also magnetic bearings and precious stone bearings but these do not occur in our car or only in exceptional cases, so we will refrain from detailing them.

However, the direction of the load must be mentioned as a characteristic, because we can distinguish the bearings from this point of view as well. If a bearing absorbs only axial forces, it is an axial bearing. If our bearing has to withstand radial forces, we are talking about radial bearings. However, the most common feature is that the bearings must withstand the load in both axial and radial directions – this is called a radial bearing. These include, for example, the tapered rolling element bearings.

The phenomenon of self-adjustment should also be mentioned. The problem that brought this to life is that it is not always possible to have the two parts that rotate relative to each other rotate on the same theoretical axis. However, smaller angular deviations can be solved with self-aligning bearings. The design of these bearings allows the shafts to move somewhat relative to each other.

Maintenance

Many bearings require regular maintenance to avoid premature failure, but there are also some that will last with minimal care. The latter include a variety of polymer, fluid and magnetic bearings, as well as rolling bearings, the description of which includes sealed bearing and life-sealed bearing. These include seals to keep out dirt and grease. They work successfully in many applications, ensuring maintenance-free operation.

Non-sealed bearings often have a grease screw for periodic lubrication with a grease gun or an oil cup for periodic oil filling. Before the 1970s, sealed bearings were not found on most machines and oiling and greasing was a more common activity than it is today.

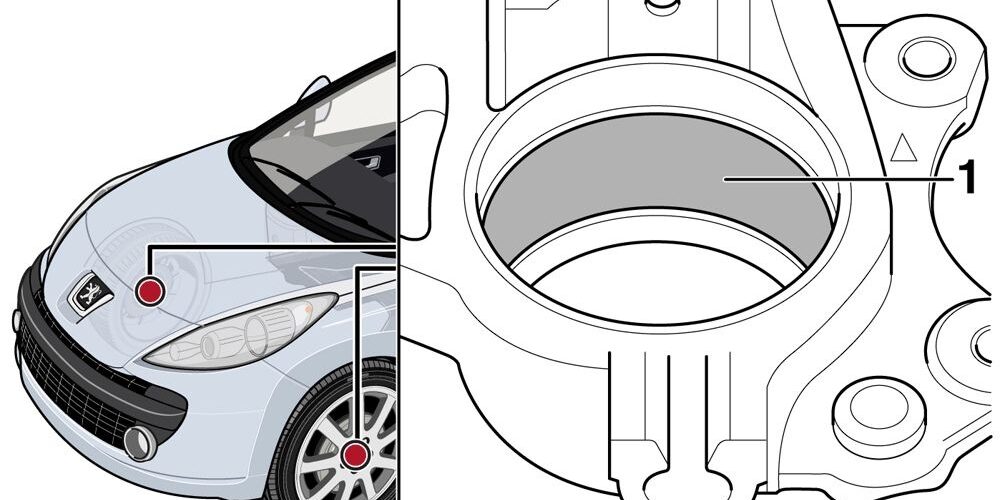

Typical bearing assembly (source: www.wikipedia.org)

For example, car chassis used to require “grease jobs” almost as often as engine oil changes, but today car chassis are mostly sealed for lifelog.

The oiling system of a modern car or truck engine is similar to a manufacturing machine’s oiling system, except that the oil is pumped continuously. Most of this oil flows through passages drilled or cast into the engine block and cylinder heads, goes directly to the bearings through the ports and splashes elsewhere to provide an oil bath. The oil pump simply pumps continuously and the excess pumped oil continuously drains back into the sump through a pressure relief valve.