Damaged column bearing of the shock absorber – do not underestimate the problem!

McPherson column bearings may seem inconspicuous, but they have a huge impact on a car’s driving behavior. They are largely responsible for driving safety – they have a decisive influence on the driving behavior of the vehicle. The BILSTEIN Academy therefore recommends regular visual inspection of these components.

Visual inspection is decisive

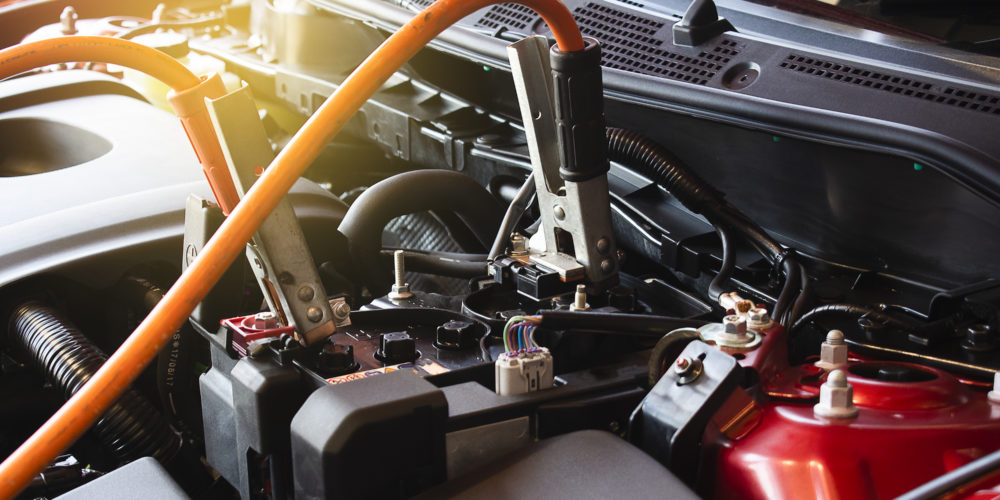

During the visual inspection (from above with the hood open), make sure that the suspension column bearings and shock absorbers are in good condition. Any corrosion that threatens these components can have potentially serious consequences: if the shock absorber bearing is damaged by corrosion, in the worst case it can even cause the upper shock absorber mount to break. For diagnostics, remove the covers from the shock absorber bearings. If corrosion is visible, the shock absorber bearings should be replaced with new ones as soon as possible.

The photo shows a solution commonly found in various Opel models, such as the Astra H and Zafira B

Also check out other elements

When checking the shock absorber bearing, also pay attention to the shock absorbers and suspension columns. If the shock absorber leaks and loses oil, it will eventually stop working properly. A damaged shock absorber bumps against the bumper, causing premature wear. The longer a car is operated with worn shock absorbers, the greater the risk that repair costs will ultimately be higher.

Be careful with heavy use

Do not underestimate the condition of the shock absorber covers – they protect the shock absorber from dirt. Particular caution should be exercised by those who frequently travel on gravel roads. Numerous small dents are easily formed on the surface of the piston rod. As a result, the shock absorber eventually begins to lose its tightness.

What to do when a shock absorber breaks?

If a visual inspection reveals that the front axle shock absorbers are damaged, they should be replaced. Improved B6 OE shock absorbers from BILSTEIN may be the optimal solution. The certificate confirms their compliance with the approval and does not require any additional testing. After installation, it is essential to verify and, if necessary, correct the suspension geometry, as well as conduct a test drive.