A miracle of a bygone era – the carburetor

It’s been a long time since we’ve been able to buy a new car whose fuel supply system – or rather its heart – is provided by the carburetor. However, before the rapid development of electricity, there was also a need for gasoline to reach the cylinders. And this device was able to do this without a single Volt.

Today’s systems are more precise and significantly more efficient, but the carburetor made its mark in that era, so its operation is definitely worth a brief technical analysis. In our article, in addition to the presentation of the structure, we also deal with its historical background.

A hazy past

Like most epoch-making inventions, the history of the carburetor is very complicated.

Currently, there is no dispute that the main version of carburetor was invented in 1893, but there are several applicants for the identity of the person. Various patents were published at various times. It is therefore possible that the Germans name Wilhelm Maybach, the Hungarians Donát Bánki and János Csonka, and the British name Edward Butler as the inventor of the carburetor.

Truth can be illustrated in several ways. In fact, ahead of the other three inventors, in 1887 the English Butler’s structure was registered in the British Patent Office, which in terms of its operating principle was the same as the Hungarian and German version. If we go even further back in time, we find the spiritual father of atomizers; In 1838, another English engineer, William Barnett, obtained a patent for a device developed to vaporize gasoline. Although there is no real atomization here, only vaporization, the whole story can be derived from this in a technical sense.

The devices patented in 1893 were much more sophisticated. The Hungarian couple preceded Maybach, moreover, they filed the claim with technical drawings from 1891. Thus, Maybach was no longer able to obtain a patent in Germany, instead he tried in France, where he succeeded half a year after the Hungarians.

Although Butler was years ahead of them, he couldn’t test it in practice due to the island’s ridiculously strict traffic laws, so he decided to dismantle it. In practical terms, the last two groups of inventors contributed the most to the development of the carburetor, but today there is no consensus as to who the real inventor is.

Principle of operation

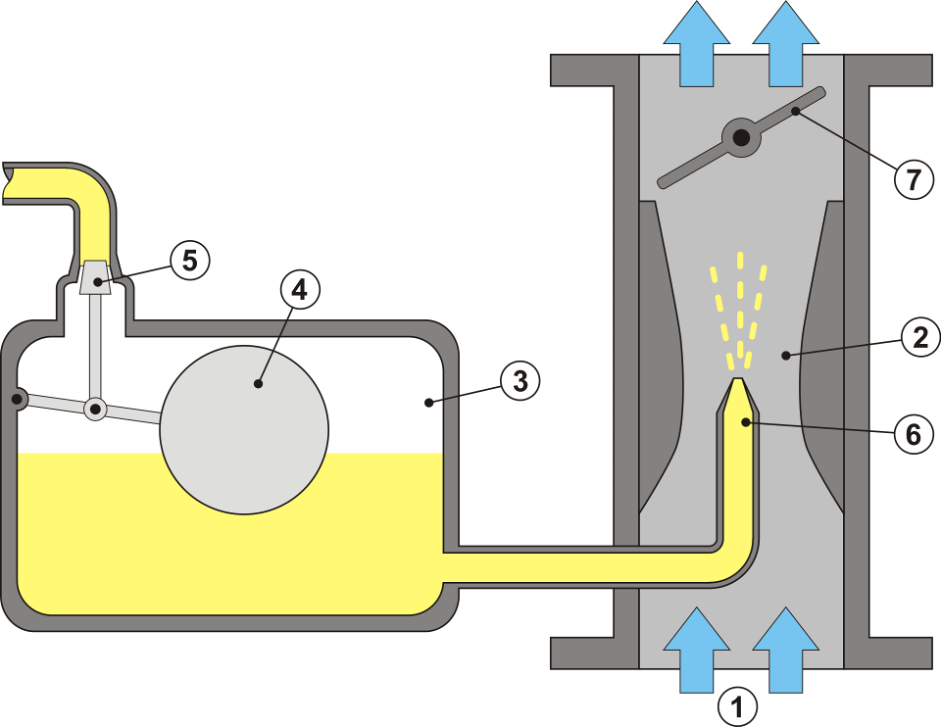

Carburetor schematic diagram (source: www.wikipedia.org)

The illustration shown in the figure above is a very simplified version of the structure. The air that is sucked in by the engine in the first stage flows into the venturi tube from below (numbered 1 in the figure), which is a confusor-diffuser pair installed in a pipe with a constant cross-section, i.e. a section of pipe with a narrowing and then expanding cross-section. This makes use of the Bernoulli rule: due to the shape, the air pressure in the narrowest cross-section is reduced, and the fuel is atomized in the form of small droplets (2) through the designed nozzles (6).

In the further sections of the pipe, the atomized fuel and air mix with each other and form an ignitable mixture as homogeneously as possible. The amount of air taken in is set by the butterfly or throttle valve (7). This is classically controlled by the position of the gas pedal.

However, the amount of gasoline entering is regulated in a completely different way. This is controlled by the system using the empty plate cylinder in the float chamber (3), i.e. the float valve (5) moved by the float (4). If the fuel level gets lower, the float will also lower, opening the needle valve.

Gasoline and air have an ideal mixing mass ratio of 1:14.7, i.e. 14.7 kg of air (more precisely, the oxygen in it) is required for the perfect combustion of one kilogram of gasoline. This can be maintained perfectly with such an elementary carburetor. The problem is that this structure can only be properly adjusted for one operating state, and the Otto engine has much more than that. When we want to get a big, possibly maximum load out of the engine, we need a much richer mixture (1:8-12.5), but for example when we want to achieve the most efficient consumption, we should use the engine around a mixture of 1:16.

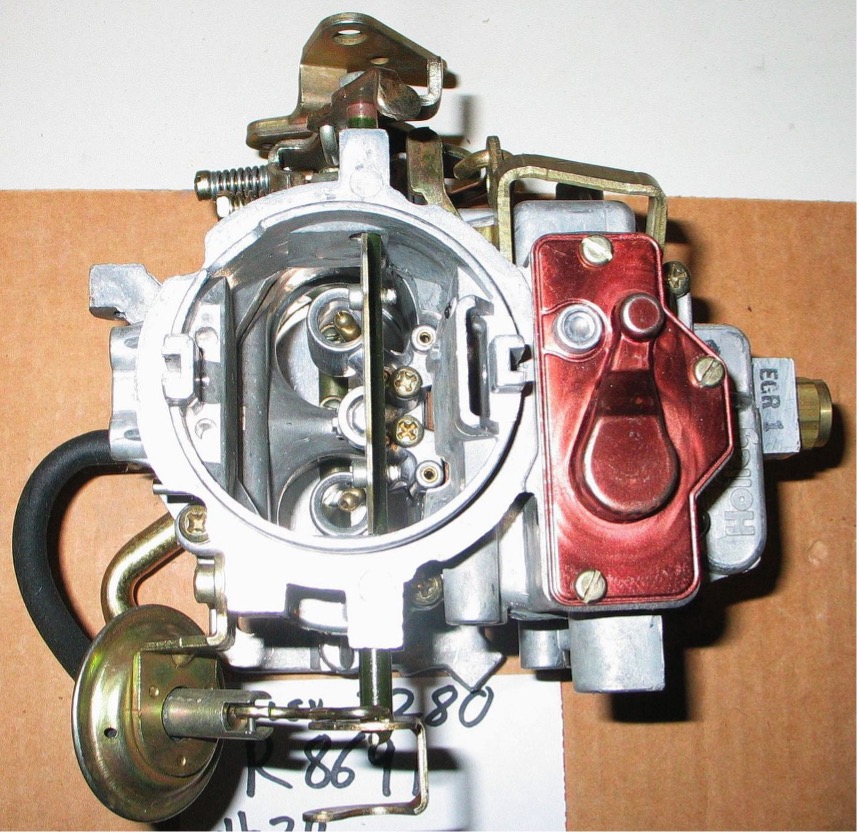

Holley 2280 carburetor (source: www.wikipedia.org)

To solve this, the carburetor was expanded with various auxiliary elements, but none of them can be adjusted perfectly for all operating conditions. The reason for this becomes clear to us immediately if we look at what exactly the mixing ratio in the carburetor depends on:

- Nozzle resistance factor: it depends on the amount of gasoline flowing through it, but not significantly because the flow rate is small

- Nozzle cross-section: this could be decisively influenced, but since the carburetor does not contain moving parts, it is always a constant value

- Gasoline density: changes somewhat with temperature, but not significantly

- Throat resistance factor and cross-section: normally these do not change either, although there have been several experiments in this regard in motorsport

It can therefore be seen that the simplicity of carburetors along with their unreliability also minimizes their flexibility, so it is very difficult for them to handle constantly changing operating conditions.

Of course, that doesn’t mean there haven’t been attempts in the past to improve it. In order for the carburetor to work more accurately even at partial load, carburetors equipped with additional solutions were used, for example carburetors with compensating nozzles (Zenith) or carburetors with brake air nozzles (Solex).

Idling is also a problem: when the throttle is closed (do not press the gas), no mixture flows to the cylinders. To eliminate this, a fine-tuned idle nozzle has been installed that bypasses the throttle and allows the idle mixture to be adjusted independently of the main flow.

The acceleration is called it was solved with accelerator nozzles, which were able to introduce more fuel into the venturi tube. The cold start could be set with an enricher, a pump known by its common name, which delivered an extremely rich mixture to the cylinders.

The end of a nearly century-long career

The end of the carburetor era was partly caused by this: by the 1980s, the environmental protection regulations had tightened to such an extent that it was no longer possible to maintain it with carburetor engines, regardless of their level of development.

The last car that could be bought new with a carbureted engine was the Isuzu Pickup in 1994, and with that the era of the carbureted petrol engine came to an end.

Source:

https://en.wikipedia.org/wiki/Carburetor

https://hu.wikipedia.org/wiki/Porlaszt%C3%B3

https://hu.wikipedia.org/wiki/Porlaszt%C3%B3#/media/F%C3%A1jl:Carburetor_Gaznik_SVG.svg

https://en.wikipedia.org/wiki/Carburetor#/media/File:Holley_2280.jpg