Optical sensors in the automotive industry

Although it does not look back on a long history in automotive technology, optical sensor technology is now an unavoidable and integral part of a modern vehicle. Image creation, especially the digital version, was initially only important for human perception in the car, but today it is mostly justified by the increasingly numerous, partly mandatory, elements of self-driving systems and driving support systems.

In this article, we write about the operation and construction of optical sensors in general, and then present some practical examples within the automotive industry.

The light

Induction sensors detect metals, capacitive sensors detect solids and liquids within their respective zones, but optical sensors are designed to detect a much more mystical phenomenon, light.

With an empirical approximation, it is thanks to the light itself that we see our surroundings – and of course to our eyes, which can also be considered an optical sensor. According to the physical interpretation, light is an electromagnetic wave consisting of photons, which is absorbed and/or reflected on the surface of particles and even smaller components of materials. The quanta of light, i.e. the energy units of the wave, are called photons.

The optical proximity switch is designed to detect these.

Operation

In practice, however, the sensors do not necessarily switch to the appearance of light – the nature of the operation always depends on what we want to detect.

Optical sensors use a combination of optical and electronic devices to indicate the presence of various objects – be it an object or some kind of material. Light, as an electromagnetic wave, is called it is detected by the system with photodiodes or phototransistors – this will be the receiver of the sensor. The great advantage of the structure is that it is mostly extremely compact. They mostly work with infrared or red light – the light source is almost always a light-emitting diode, i.e. LED – this will be the transmitter of the sensor. The LED itself is GaAlAs, the wavelength depending on the composition is 880 nanometers for infrared, 600 nm for visible light emission.

If the sensor works with visible light, its adjustment is significantly easier, since the optical axis of the light source can be detected with the naked eye, and the attenuation of polymer light guides in this wavelength range is relatively small.

Infrared light also has a practical use: it should be used when greater brightness is needed – this usually happens when we want to bridge a greater distance with the light beam. In addition, another advantage of the infrared range is that the effect of disturbing light phenomena from the environment affects the operation of the sensor less.

Of course, this does not mean that sensors cannot be tampered with. In order to eliminate, but at least significantly reduce, the disturbing effects of the environment, the optical signal is modulated, and in the case of infrared sensors, light filters are also successfully used. The pulse rate of the transmitter and the receiver are synchronized.

The following switching states are distinguished for one-way and reflection light gates:

- NO, i.e. normally open: the output of the receiver closes if the path of the light beam is not interrupted by any foreign body or material.

- NC, i.e. normally closed: the output of the receiver closes when an object crosses the path of the light beam.

Similar conditions can also be seen in the case of object reflection proximity switches:

- NO: the sensor output closes if there is a body or material in front of the sensor.

- NC: the sensor output closes if there is no object in front of the sensor.

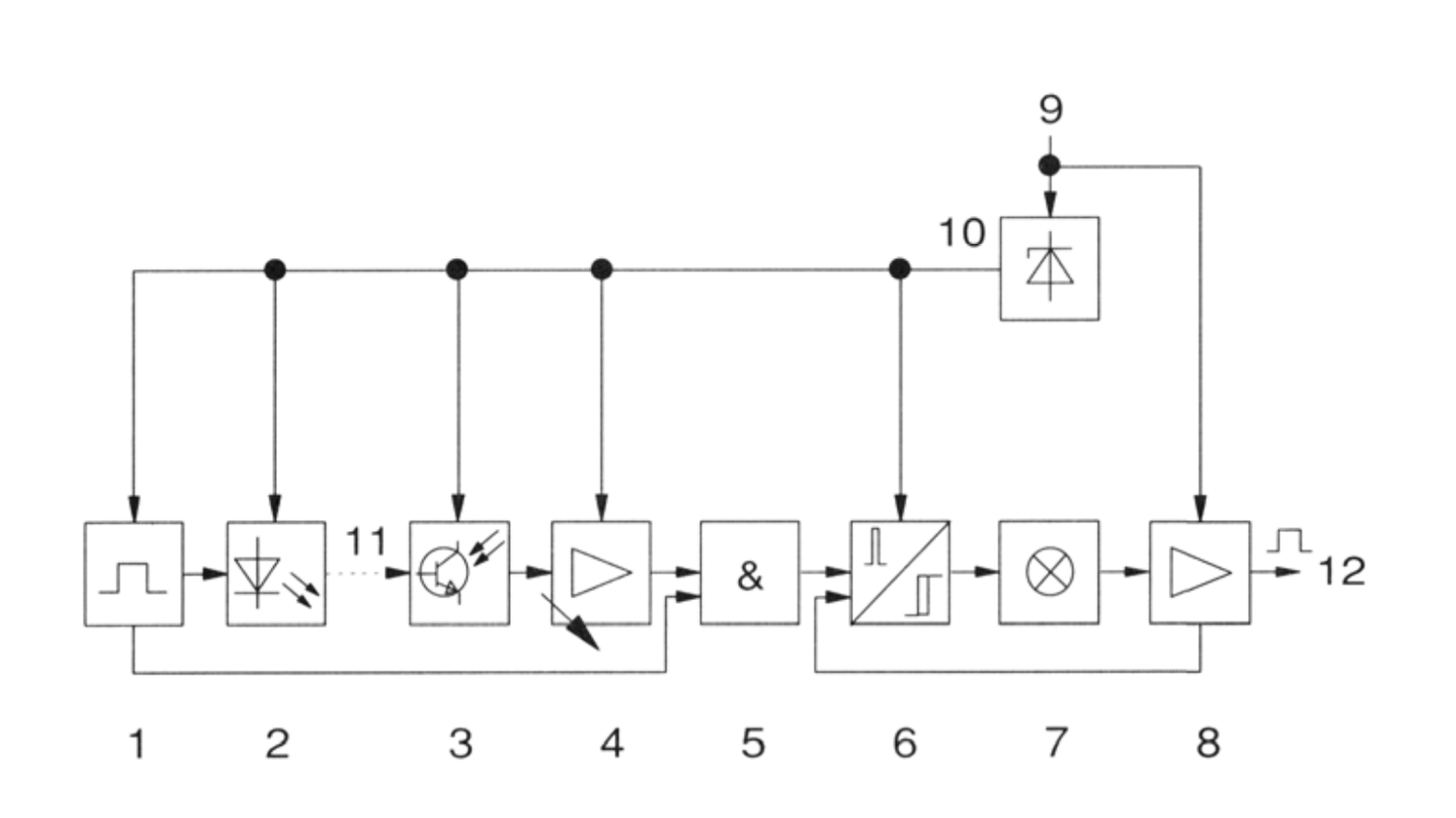

Principle connection of a reflective optical sensor: 1 – Oscillator, 2 – Photoelectric transmitter, 3 – Photoelectric receiver, 4 – Preamplifier, 5 – Electronic coupling, 6 – Pulse/signal level conversion stage, 7 – Switching state display, 8 – Output stage with protective circuit, 9 – External voltage source, 10 – Voltage stabilization, 11 – Optical section, 12 – Switching output (source: www.wikipedia.org)

Special versions: cameras

Cameras occupy a special place in the palette of optical devices. A very significant difference between traditional optical sensors and cameras is that, while the former can only detect changes affecting their light beams, cameras are capable of creating complete images from the light-based information received by their sensors. This opened a whole new door for many industries.

It collects the light through an optical system, which it projects onto an opto-sensitive surface, which then converts the intensity and frequency of the electromagnetic radiation into information. This used to be done chemically, but today it is done purely electronically.

The advent of digital imaging gave a huge boost to the development of camera technology. In recent decades, several imaging principles (such as CCD or CMOS) have appeared, which are increasingly used by the automotive industry, among others.

One of the main characteristics of cameras is the sensor size. This is usually given in inches. An interesting fact is that the nominal value is usually not the same as the real size of the sensor. Standard 1” circular lenses have a roughly 16mm photosensitive rectangular surface.

Another important parameter is the resolution, i.e. the number of pixels that can be displayed. The higher the resolution, the smaller the pixel size for the same lens size. As a result, higher resolution is not ideal in all cases, since smaller pixels are less sensitive to light and can generate more noise.

CMOS technology

Today, there are many digital imaging methods – we will briefly highlight one of them.

CMOS (Complementary Metal Oxide Semiconductor) is a combination of a P and an N type MOSFET. Each image element has a separate amplifier, so it amplifies the charges per pixel – that’s why they are also called active pixel sensors.

Previously, CCD sensors were preferred because they were more sensitive and worked with less noise. Now, however, thanks to developments, CMOS has become competitive in all respects and can be considered the most common version.

Optical sensors in cars

Various self-driving and ADAS systems are practically unimaginable without optical sensors. Many self-driving systems use, for example, LIDAR, which is a laser-based distance sensor, but Tesla only solves the car’s self-driving functions with cameras.

Without optical sensors, this self-driving minibus would be immobile (source: www.pixabay.com)

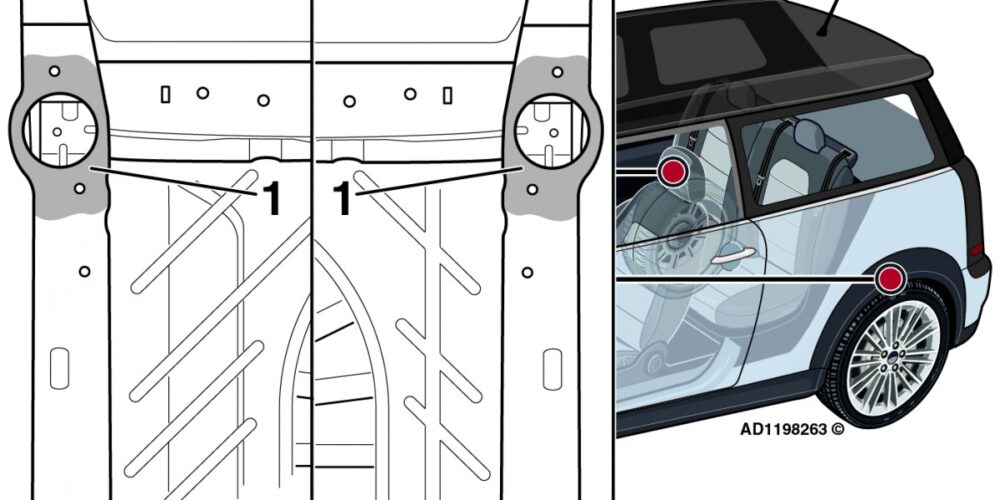

The front, rear and side view cameras and/or lasers of ADAS systems are also essential, but also the optical sensor half for the real-time, dynamically changing operation of the matrix LED headlights.

https://www.fierceelectronics.com/components/optical-sensors-are-a-key-technology-for-autonomous-car

https://oktel.hu/szolgaltatas/kamerarendszer/kamerak/ccd-es-cmos-erzekelok/

https://www.opto-e.com/en/basics/cameras

https://www.ipari-elektronika.com/az-optikai-szenzorok-mukodesi-elve-es-fobb-jellemzoihttps://pixabay.com/photos/vehicle-autonomous-4759347/