Volkswagen’s own supercharger

In the recent period, we have presented several charging methods for internal combustion engines. As time progressed, more and more interesting solutions were created, many of them remained on the design table but quite a few reached serial production.

Although the world of compressors was dominated by the United States, Volkswagen concern did not want to be left out – and to fall behind in the development competition, so it tried to come up with its own idea, so demonstrating the innovative potential that characterizes the brand group. In the following article, we present how the German manufacturer wanted to dominate the market of mechanical chargers.

The German charger, which is not from Germany

The extent how Volkswagen conquered the market with the G supercharger will soon become clear in the article – however, we can tell that the solution made famous by the German company group was not originally their own intellectual product.

What’s more, the invention was not even patented in Germany. On October 3, 1905, a French writer and engineer named Léon Creux obtained the patent right for the so-called for a scroll type compressor (US Patent No. 801,182).

The inventor’s name fell into obscurity and this was due to the fact that his idea was not applied to almost anything for a very long time. The principle was functional but the manufacturing technology in the 1900s was not yet at the level to produce the tolerances, fits and material quality required for operation.

It took until the 1980s, so almost a century, for the concern managed by Volkswagen and Audi to make the compressor famous.

The company group saw the scroll-type compressor as a kind of challenge, since everyone stayed away from the implementation of the idea because they considered it either unreasonably expensive or impossible to implement.

Then VW-Audi called it the G supercharger and started designing.

Structure, operation

The structure of the G supercharger does not appear to be complicated at first: the charger consists of a two-part housing, an alternately moving compressor and the drive and auxiliary shafts. The filling chambers, which are responsible for the creation of compression, are arranged in a spiral in the already mentioned two-part housing – hence the name scroll-type compressor.

Schematic diagram of a scroll type compressor (source: www.wikipedia.org)

While the part of the compressor that “spins” makes an alternating motion, the spirally arranged chambers ensure that the air is conveyed.

As with all mechanical chargers, we can say that the charger’s energy needs are covered by the internal combustion engine. Of course, this means that the G supercharger also takes useful power from the engine, but at the same time it works particularly efficiently even in a low speed range, unlike the turbochargers used at the time.

The drive typically comes from the main shaft of the engine with a V-belt drive, the auxiliary shaft is driven by a ribbed belt. The loader is moved by the axles with the help of cams, which thereby performs a circular oscillating movement. The direct consequence of this is that the amount of air delivered by the scroll-type compressor, also known as the worm supercharger, is proportional to the engine’s own speed (both the “screw” and “G” names refer to the shape of the supercharger).

In this way, we avoid the turbo hole, which was a serious problem at the time and is now almost insignificant, and – thanks to the excellent efficiency of the G supercharger – it performs outstandingly even among compressors at low rpm. Its efficiency can be higher than 60%, depending on the design.

If the entire air charge is not needed, a part of it is transferred to the suction side by the supercharger via a pressure regulator. Since the G supercharger increases the volumetric efficiency and charge level in the entire speed range of the internal combustion engine, high torque flexibility can be achieved with its application.

Passenger cars with G supercharger

Although the scroll-type compressor did take shape and hit the road thanks to Volkswagen, since the company crawfished from the technology relatively quickly, the solution was included in few models.

It is easy to identify them: vehicles with G40 or G60 engine codes received G superchargers.

These are the following types:

- Volkswagen Polo Mk2 GT G40 (86c – first series limited to 500 vehicles (all black, fog lights) and second series approx. 1 500 units, base colors plus 500 all black, sold only in the French market)

- Volkswagen Polo Mk2F GT G40 (86c)

- Volkswagen Golf Mk2 GTI G60 (19E)

- Volkswagen Golf Mk2 G60 Rallye (19E – limited to 5000 vehicles)

- Volkswagen Golf Mk2 G60 Limited (19E – limited to a special Volkswagen-Motorsport series of 71 vehicles)

- Volkswagen Corrado G60 (Corrado – 53I)

- Volkswagen Passat (B3) G60 Syncro (Passat – 35I)

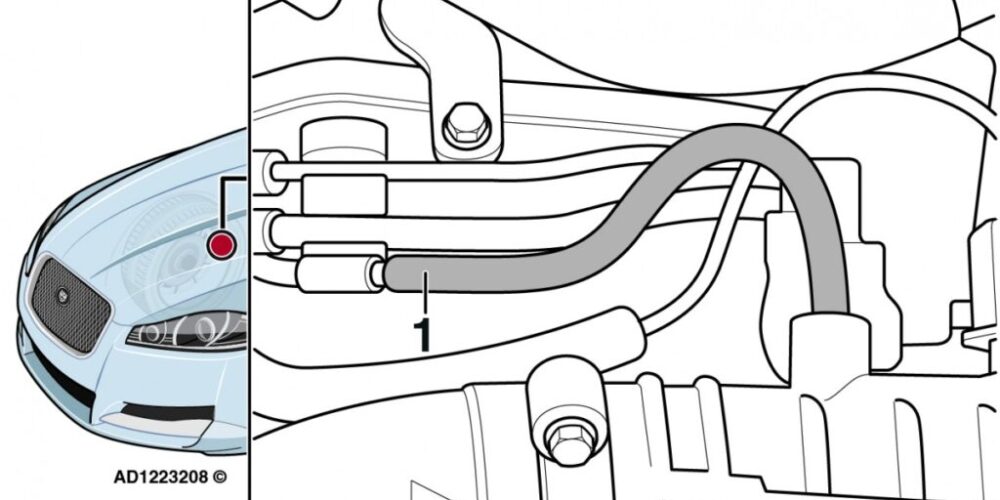

G supercharger from a Volkswagen Corrado G60 (source: www.wikipedia.org)

The reason why Volkswagen ended the G charging project

The concern wanted to come up with a scroll-type compressor that is practically maintenance-free, so its lifespan is equivalent to a car’s lifespan. This is how the concern presented it to its potential customers at the time.

However, in reality, this statement did not completely cover the reality. In normal operation, the G superchargers required relatively frequent servicing and repairs. Depending on the load, speed and other parameters, the parts of the G supercharger wear out. Thanks to this, it starts to lose its performance until it finally breaks down and needs a complete renovation. Some believe that they can detect similarities with the behavior of Wankel engines.

With appropriate periodic services and component replacements, the service life of the scroll-type compressor can be extended to a very long time, even hundreds of thousands of kilometers. However, this was not enough for Volkswagen to mobilize additional energies in the project, so it stopped its development and then its production.

Many people still consider the G superchargers as benchmark but in general it can be said that the higher-than-expected service requirement and the resulting extra costs did not make it marketable against the competition, so no one has used the solution in road vehicles since then.

Source:

https://en.wikipedia.org/wiki/Scroll-type_supercharger

http://cyrax86.web.elte.hu/alk/tuning/gtolto.html

http://ahturbo.com/technikai-info/egyeb-feltolto-rendszerek/

https://en.wikipedia.org/wiki/G-Lader

https://en.wikipedia.org/wiki/G-Lader#/media/File:Corrado_G60_Supercharger.jpg

https://en.wikipedia.org/wiki/G-Lader#/media/File:Two_moving_spirals_scroll_pump.gif