The Future is Now: The Latest Trend in Brake Systems Gains Popularity

The brake system can undoubtedly be considered the most crucial component responsible for road safety. The first brake systems were based on a mechanical lever system. With the development of the automotive industry, the well-known hydraulic systems, which have been popular since the 1920s, emerged. Today, with the rise of electric vehicles, a new generation of brake systems is taking shape. What will brake systems look like in the near future?

New Mobility Brings New Challenges

When hydraulic brake systems were developed and introduced in the 1920s, not everyone was convinced of their safety. A similar situation can be observed today, as servomotors are gradually replacing vacuum-based brake boosters in modern cars. Trust in electronics, specifically their reliability, is not very strong. It’s no wonder there are concerns when it starts to occupy such an important place in our safety.

However, there’s another side to this story. In the United States, a new trend is gaining popularity. Classic car enthusiasts are using the latest automotive technology to improve the effectiveness of the brake systems in their classic Mustangs, Cadillacs, and many other cars. It turns out that the iBooster, an electric brake booster made by Bosch, used in cars like the Tesla Model 3 and the Honda Accord, can be easily adapted to classic cars. Those who have made such modifications praise the improved responsiveness of the brake system and the feeling of driving a modern car. It’s also important to note the improved engine efficiency, as it no longer needs to generate additional vacuum.

Interestingly, the first models of Tesla cars used an electric vacuum pump connected to a traditional brake booster. It was only later that engineers decided on an electric brake booster, which ultimately is cheaper and more effective than its predecessor.

The Path to a Dry Brake System

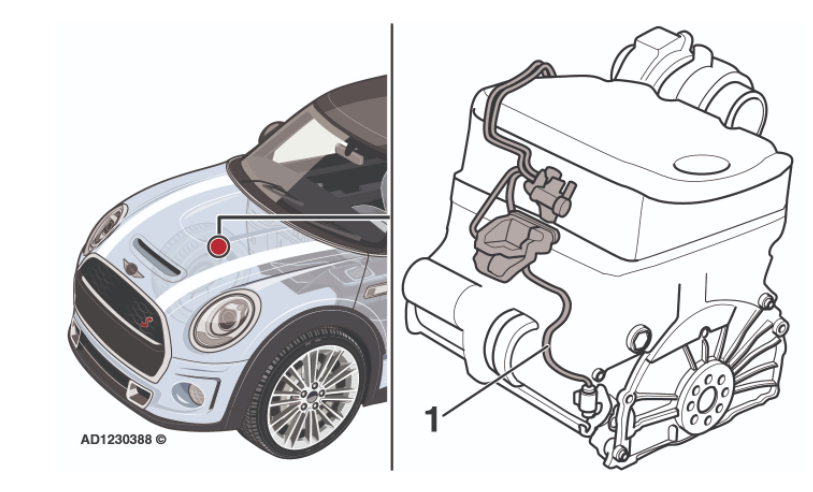

While electromobility has accelerated the development of electric brake boosters to eliminate the need for a vacuum pump, the elimination of brake fluid will not be as easy. Brake system manufacturers plan to gradually electrify the braking process. The first step was the introduction of electric brake assist devices like Bosch’s iBooster and TRW’s Electronic Brake Booster (EBB). These are controlled by a built-in controller in conjunction with the CAN BUS system, ensuring that the braking force and switching moment from regenerative braking are precisely matched to the speed, road conditions, and many other factors. This technology is also ready for the future of autonomous vehicles, as braking can occur without human intervention. Moreover, in electric and hybrid vehicles, this system allows for light braking using only the regenerative system.

The next stage will be the semi-dry brake system. Continental’s technology is gaining significant popularity in this area. The brake system designed by their engineers consists of electric brakes on the rear axle and a hydraulic system, with an electric servo, for the front wheels. This solution offers car manufacturers a lighter, simpler construction, higher precision, and lower cost of the brake system. The brake servo used in the brake system designed by Continental engineers, similar to Bosch’s iBooster, has a physical connection to the brake pedal.

The latest brake system presented by Bosch is a semi-dry system utilizing Brake-By-Wire technology. Bosch’s solution is based on a brake pedal that sends an electric signal to the brake pump. Thanks to this technology, the brake pump can be installed anywhere, no longer needing to occupy space in the engine compartment.

Dry Brake System or Brake-By-Wire

The announcements of the largest OE manufacturers unequivocally indicate that soon brake systems in new cars will be completely devoid of hydraulics. Brake lines will be replaced by cables, and the brake pump will be replaced by electric actuators integrated with brake calipers. ZF has already presented their solution for this.

The brake system without brake fluid by ZF boasts up to 9 meters shorter braking distance and enables a 17% higher range for electric vehicles due to more efficient energy recovery via the regenerative system. Additionally, ZF highlights economic benefits: The elimination of the hydraulic system means significantly lower assembly and logistics costs even during vehicle production, as the system consists of fewer parts. The user also benefits during the vehicle’s operation period, as there is no longer a need to replace brake fluid, reducing the number of service activities required.

It is no secret, however, that electronics do not enjoy full trust among car users or mechanics. Traditional brake systems, and even those utilizing electric servos, allow for braking even in case of vacuum or power failure. What safety systems are used by Brake-By-Wire manufacturers? We asked a representative of ZF this question.

“Like brake systems with brake fluid, dry Brake-By-Wire systems require two electrical circuits—power sources, central ECU, and connections—to maintain redundancy and operate even in the event of a failure. Additionally, ZF EMB’s Brake-By-Wire system with four intelligent actuators is inherently redundant, as the braking force of the brake calipers can be balanced if needed in case one fails. Moreover, ZF EMB’s intelligent actuators can detect and even predict potential failures and take appropriate preventive actions. This was not possible with conventional hydraulic systems and makes dry Brake-By-Wire systems exceptionally well-suited for autonomous vehicles,” says Diego Cusi, Director Engineering, Foundation Brake Core & EMB, ZF Group.

The electric revolution brings changes not only in the area of the powertrain but also in other components present in cars. Is the full electrification of brake systems the most likely vision of the future? Will drivers be able to trust electric brakes? Many indications suggest that history may repeat itself. What is new and uncertain today may become a widely accepted standard tomorrow.