Test of the Magneti Marelli air conditioning service stations – conclusions

Over the past two months, our partner garage tested two Magneti Marelli air conditioning service stations from the new Alaska Prime and Alaska EVO lines. Even though the season hasn’t yet started, the team managed to convince quite a few drivers to have their A/C systems serviced. Thanks to them, we have compiled a list of comments and thoughts regarding the tested stations, which will certainly be useful for anyone interested in a purchase.

Operation of the Magneti Marelli Alaska Prime and EVO stations. Everyday impressions.

We made a preliminary introduction of the tested units in the first article about them. You can read it HERE. Just to remind you – we tested the stations from the new product lines that have recently expanded the offer of Magneti Marelli. Alaska Prime is a budget line, intended to provide a favourable ratio of functionality to price, whereas EVO line are top products of the brand, which are their flagship products.

In the test set, the Prime line budget station was equipped to work with the new R1234yf refrigerant, and as an (optional) accessory, had a refrigerant identifier. Alaska EVO station was equipped to work with the old refrigerant – R134a, and in comparison to the base version, it included an integrated printer as additional equipment.

The servicemen in our garage attended a demonstration and initial training on how to operate the units. The garage had previous experience with servicing air conditioning systems; this type of service has been on offer for six years. This is also how old the currently used service stations were – from one of the major manufacturers. Compared to them, was the daily work with Magneti Marelli stations easier or more burdensome?

“I must admit that we needed some time to switch over,” says Krzysztof Włodarczyk, the owner of the garage in which the test was held. “Our old machines only allowed manual operation of the system, while in Magneti Marelli stations many functionalities have been automated. So we don’t have total control over the process, but that doesn’t actually bother us. We can also work in manual mode, but this automation is beneficial to the servicemen, it speeds up their work – just takes some getting used to. When we do the service in automatic mode, we can basically simultaneously do other things, which saves a lot of time. If something goes wrong, the machine will abort the process and show us the cause of the problem.

Our servicemen also noted the ease of use of these stations, they guide the user step-by-step preventing them from making any mistakes. They found, however, that, after some time, they would like to do some procedures quicker…”

“Magneti Marelli stations are suitable for people who have had little to do with air conditioning service so far – are certified to do this service but are not experienced in it. The machines tell you what to do and in what order. For experienced operators, this procedure can become a bit annoying over time. There is no way to speed up service here,” adds Krzysztof Włodarczyk.

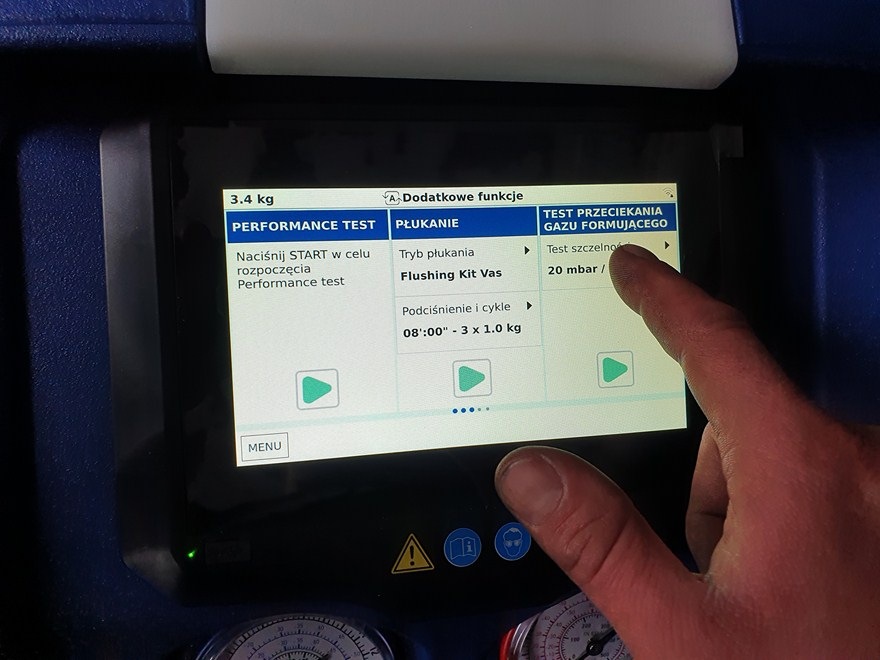

The servicemen reported similar feelings about the performance test the machines always perform at the end of A/C system service. It takes some 3-4 minutes and verifies that the air conditioning system is fully operational. According to servicemen, the test is not always necessary – for example, after repairing the system, when we know that it is fully operational, additional confirmation is not required. In our humble opinion, however, it is difficult to consider the additional procedure of checking the integrity of the A/C system as a disadvantage, especially since it can be interrupted at any time or cancelled altogether (the service station asks whether it should carry out this test).

While working with the units, the servicemen noted the solid performance of the integrated pump. Interestingly, it is a relatively small pump – providing a flow rate of 50 l per minute. In some commercially available machines there are even pumps offering performance of over 200 l per minute. So why these observations of the servicemen?

“Despite the theoretically low flow rate, the pump performs very well because it is optimally calibrated. It is very important for the pump to maintain a stable negative pressure in the process of generating a vacuum and in the sealing test process,” says Grzegorz Toczyński, Magneti Marelli Technical Service Specialist.

After the test, the servicemen agreed that the pump maintained pressure very well even when servicing vehicles with leaks in the A/C system. When generating a vacuum in the system, its level drops very quickly to -1 bar and is maintained in a stable way throughout the process.

Operating modes – Alaska air conditioning service units

After getting used to operating the new units, the servicemen began to appreciate the primarily automatic mode of operation, which proved to be suitable for servicing most of the vehicles they work with. This mode runs on a large touchscreen for the EVO station or a monochrome display for the Prime station. The software guides the user through the process step-by-step.

For EVO and Prime stations, you can select the serviced vehicle model from the list at the appropriate time. Once this is done, the unit automatically assigns the A/C system data for the vehicle – the operator can view them. Based on the technical data of the vehicle, the station automatically selects the amount of oil to be used during service. If the operator would like to change the settings, e.g. increase the amount of oil because the condenser in the system has been replaced – they can do it manually by selecting the appropriate additional value. If the operator accepts the default parameters, the process can be confirmed with a single press, and the machine performs the operation automatically. If a problem occurs during the process, the operator will be notified by an on-screen message. However, this does not mean the service must then be completed in manual mode. The station has a function, which enables safe filling of the system in difficult working conditions.

“All of our machines are equipped with Secure Charge, which is an A/C system safe filling feature. This is a patented method that allows the refrigerant to be charged into the system under difficult conditions. Such conditions mainly occur in summer when temperatures are high. When this happens, the vehicle’s air conditioning system is at high pressure, making it difficult to recharge the refrigerant. The unit does this not by means of a heating belt, fastened to the cylinder, as it happens in competitor’s stations, but thanks to a special control system. It injects the refrigerant through one hose, pulling it out of the system with another and at the right moment (when the set value is reached) it cuts off the flow, leaving the system recharged. The procedure does not take long, it speeds up the work, it works even in extreme conditions on hot days,” says Grzegorz Toczyński from Marelli.

There were no hot days during our test, but the EVO station did surprise the servicemen when it encountered a problem during recharging the system while in automatic mode (which could have been caused by the low outside temperature – frost, Monday morning in a garage that had not yet warmed up). The station displayed a message asking to close the high-pressure valve and turn on the vehicle’s air conditioning. It then started the low pressure filling mode and worked in pulses until the set value was reached. The servicemen have filled the system this way in the past, but always in manual mode.

Magneti Marelli Alaska Prime and EVO – distinctive features

The servicemen quickly got used to the Magneti Marelli service stations. Throughout the test period, they noted no errors or incomprehensible machine “behaviour” that was not caused by operator error. There were, of course, no failures either, which, with such a short test period for new equipment, would have been of particular concern. However, if they did happen, the maintenance technician would only have to come for one of the stations tested – the budget Prime model. The EVO station has a built-in Wi-Fi module for remote diagnostics. Marelli service is able to connect to the station remotely and check the cause of the fault. In many cases, it is possible to resolve the issue remotely or give the operator instructions on how to proceed. In the case of a more serious failure and, for example, the need to replace a component, the maintenance technician of course comes to the garage. Magneti Marelli stations are covered by a two-year warranty counting from the date of commissioning the unit (entering the unlock code).

Proper maintenance is required to keep the stations running reliably for as long as possible. In the case of the stations from the Alaska line, the operator does not have to note down the appropriate intervals in a calendar. The machines themselves remind the operators of the required maintenance procedures. One particularly important functionality of the units is the oil regeneration function in the pump. All Magneti Marelli air conditioning service stations offer this functionality.

“After switching on the unit, after the appropriate time interval (7 days by default), the machine asks the operator whether to perform oil regeneration. If this procedure is confirmed, the unit cleans the oil in the vacuum pump, extending its life. At maximum, if we follow the schedule of these activities, i.e. systematic regeneration, we can extend the service life up to 1000 operating hours and avoid the need for frequent oil changes in the pump. The regeneration process takes about an hour,” said Grzegorz Toczyński, Magneti Marelli’s Technical Service Specialist.

Magneti Marelli Alaska Prime and EVO stations – servicemen opinions

Both stations included in our test received good reviews from the servicemen who operate them. As the main advantages of the Alaska EVO station they pointed out the convenience and clarity of operation, thanks to a large touch screen and cylinder-lifted housing, allowing access to station components by releasing a single lever. Wi-Fi connectivity provided by the station was also a convenient feature for the garage. Air conditioning service reports can be sent directly to a company computer and displayed there or sent to the customer. The tested station also had an integrated printer, which is available from Marelli as an optional accessory. It allows the operator to print the report immediately after completing the service, without having to go to the computer. This is by far the fastest solution. However, both tested units are also equipped with a USB port, so reports can be saved to a flash drive.

The Alaska Prime station, as a lower-priced device, does not match the EVO station in terms of convenience or speed of operation. However, it does have its advantages. First of all, it’s a lot cheaper. Our test involved a Prime station set up for the new refrigerant. In the garage where the test took place, vehicles using R1234yf refrigerant are much less common. A common trend among owners of newer vehicles is to replace the factory R1234yf refrigerant with the older R134a at the first major system service. The reason is simple – lower price of the old refrigerant. The garage staff noted that the set of two stations they were provided for testing was adequate for their needs. The budget Prime station was used less frequently. The garage owner admitted that buying a top-of-the-line station for the new refrigerant would be an investment for him that would take quite a long time to pay for itself.

However, price is not the only advantage of the Prime station over the EVO. Counter-intuitively, its smaller size and more modest equipment (no oil scale) comes in handy for non-typical applications. The small Prime station is easy to fit in the trunk and take into the filed – for example, to service the air conditioning in construction or agricultural vehicles that are not allowed on public roads. The simpler oil feeding system is resistant to shocks and vibration. There is no concern about damaging or upsetting the scale because it simply isn’t there.

The ALASKA PRIME station tested by us supports systems filled with the new R1234yf refrigerant

The Prime station we tested had one of the optional accessories that received rave reviews from servicemen. We are talking about the refrigerant identifier. According to garages, this device is very useful because of the popular trend to fill the A/C system with different gas rather than the originally used refrigerant. If there is uncontaminated refrigerant in the system, the identifier displays its name. During the test, it happened that in a vehicle set up originally for the R1234yf refrigerant, the identifier detected pure R134a gas. In the case of heterogeneous mixtures, the device will be able to tell the composition of the gas, but will warn the user that the system is filled with something else than it should. According to servicemen, propane-butane or carbon dioxide can be found in air-conditioning systems in second-hand vehicles sold by some “dealers”, which are usually brought to the garage almost immediately for various types of repairs. The goal of the seller is simple – to temporarily get the air conditioning system working again. However, the garage serviceman is never sure what gas is in the system and how to recover it, so a working refrigerant identifier is a very useful tool.

A/C refrigerant identifier

Is it worth buying Magneti Marelli stations from the Alaska Prime and EVO lines?

Based on the opinions of servicemen and our own observations, we can consider the stations provided for our testing to be worthy of recommendation. They are good quality units, made in Italy, with many features that proved useful and reduced labour intensity. The Alaska EVO station is, of course, a particularly interesting proposal with a good number of innovative technical solutions. The Prime station, on the other hand, is a decent budget piece of equipment, ready for both garage and field use.

The purchase of an air conditioning service station is a serious investment, so the Magneti Marelli’s price offer is worth a careful consideration. In comparison with direct competitors offering similar solutions, the Italian brand comes out fairly well. Of course, it’s always a good idea to check for additional discounts, so we recommend contacting the company representatives directly. We hope you can get an additional discount using the code “MOTOFOCUS” as a reward for getting to the end of this article.