Fuel Tank with Carbon Filter – Symptoms of Failure and Repair Method

The fuel vapor recirculation system aims to protect the environment, protect the driver and passengers from fuel vapor poisoning, and safeguard against fuel vapor explosion. The fuel tank with carbon filter is the most important part of the fuel vapor recirculation system. Can it break down? What are its failure symptoms? We’ll ask an expert.

“The fuel tank with carbon filter is a key element of the fuel vapor recirculation system, crucial for meeting emission requirements in motor vehicles. Thanks to this solution, which is an integral part of the lambda probe regulation system, it’s possible to effectively separate and store volatile hydrocarbons before they are burned,” explains Roman Wierzbowski, category manager from FORVIA.

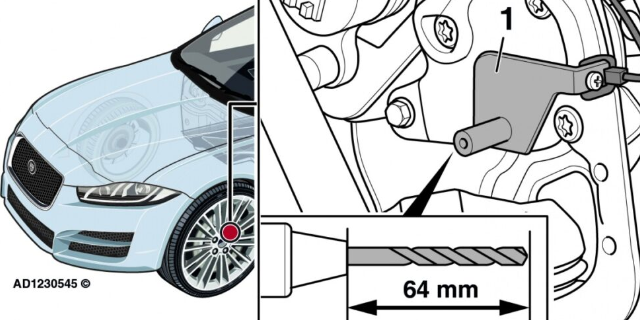

The fuel vapor recirculation system consists of a solenoid valve and a container with a carbon filter. The solenoid valve and carbon filter are mounted in the engine compartment. The regeneration valve is usually mounted near the intake manifold. The carbon filter is typically placed in the car’s wheel well, in a specially sealed container.

The solenoid valve is controlled by the computer that manages the operation of the drive unit. Therefore, it’s necessary to connect the solenoid valve to the computer via a power-signal wire.

Three lines are connected to the container with the carbon filter:

- The first line is the fuel tank ventilation line;

- The second line leads from the intake manifold before the throttle;

- The third line is from the intake manifold after the throttle.

How does the fuel vapor absorption system work?

Fuel vapors are formed when the fuel is hot. Fuel heats up from the outside air temperature, from the electric fuel pump submerged in the tank, or from the injection pump that compresses it – if the fuel hasn’t been burned and returns to the tank.

“The tank with carbon filter is connected to the fuel tank ventilation system via a pressure compensating line. When the lambda regulation system is activated, the pulsing valve opens the line between the intake pipe and the tank with carbon filter, allowing air from the environment to be sucked through the activated carbon. This process allows the separated fuel to be reintroduced to the engine and mixture preparation system, ensuring an optimal fuel-air mixture composition,” explains Roman Wierzbowski.

Symptoms of failure of the tank with carbon filter

How long does a tank with carbon filter last? Theoretically, it should last at least 15 years, but this can vary.

“Like almost any vehicle component, such a tank can fail. Symptoms of such failure may include improper flow in the fuel tank ventilation system, which can lead to increased emission of harmful substances into the atmosphere and a noticeable gasoline smell. The causes of failure can be diverse, from improper control by the controller, through damage to the pulsing valve, to mechanical damage caused, for example, by an accident or damaged lines,” explains Roman Wierzbowski. “Therefore, regular inspection and maintenance of this element are extremely important to ensure proper vehicle operation and compliance with emission standards, which translates into protection of the environment and human health.”

How to check the tank with carbon filter?

Checking the tank with carbon filter should include the following activities:

- Checking the condition of the tank for mechanical damage – due to its location in the wheel well, it may be damaged.

- Checking the tightness of the hoses and their correct attachment.

- Checking the proper connection of the power-signal wire and the condition of the connectors in the pulsing valve.

- Checking the ground and supply voltage at the pulsing valve connectors. An oscilloscope will be necessary in this case.