Diagnostics of car suspension bushings

Suspension bushings (also called silent blocks) are key elements in a car’s suspension system. Their main task is to dampen vibrations and noises that arise during driving, and to ensure driving stability and travel comfort. Bushes connect metal elements of the suspension system, such as control arms, wishbones, stabilizers or suspension beams, to the vehicle frame, absorbing shocks and reducing wear of other components.

What are the functions of suspension bushes?

Suspension bushes are usually made of rubber or polyurethane and fulfil several important functions:

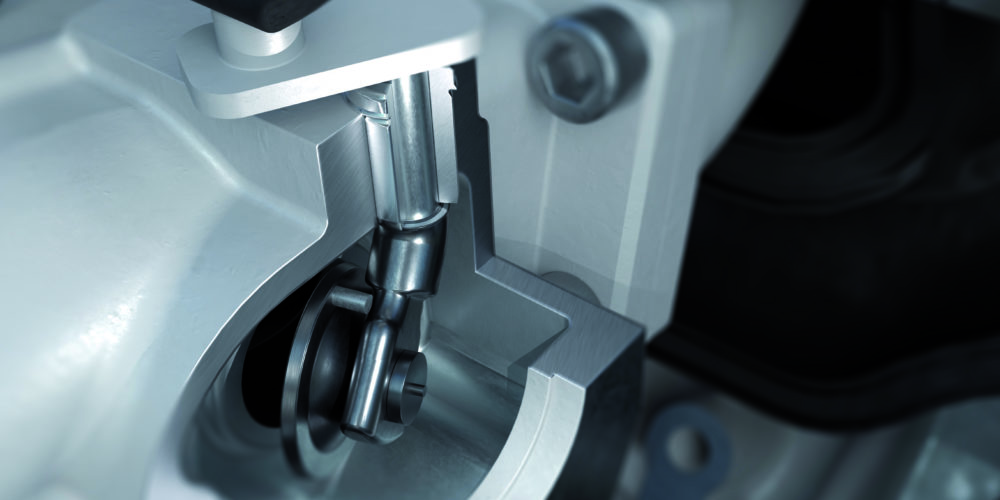

Uniball connection

- Vibration and noise dampening. Rubber or polyurethane effectively dampen vibrations that occur when driving on uneven road surfaces, especially when it comes to vibrations of small amplitude. Spring and shock absorber systems are responsible for vibrations of larger amplitudes.

- Connecting metal elements. Bushings serve as flexible connections between metal elements, which prevents direct metal-to-metal contact, which could lead to rapid wear and damage, and above all, would cause the transfer of vibrations, and would also contribute to the generation of noise in the system. Metal connections (using a Teflon coating) are used practically exclusively in the case of motorsport, where driving comfort is relegated to the background. An intermediate solution in this case may be the use of polyurethanes, which, while sacrificing comfort, offer better driving properties than rubber elements, but at the same time do not stiffen the entire system like uniballs.

- Increasing driving comfort. Thanks to their ability to absorb shocks, the bushes help to smooth out the vehicle’s ride characteristics and reduce unpleasant shocks that could be transferred from the suspension to the vehicle interior.

What are the symptoms of damaged bushings?

- Unusual sounds

One of the first symptoms of damaged suspension bushings are various types of sounds coming from under the vehicle:

- Tapping sound. Often heard when going over bumps or when turning. A tapping sound may indicate excessive play in suspension connections.

- Creaking noise. It can be caused by abrasion of the rubber parts of the bushings or their wear. The creaking is usually heard when driving slowly and turning the wheels.

- Vehicle instability

Damaged bushings can cause vehicle stability problems:

- “Floating” vehicle. The vehicle may feel unstable, especially when cornering or driving at higher speeds.

- Movement of the axis. Worn bushes can cause the axle to move relative to the body, affecting steering and stability.

- Tire wear

Improper suspension operation can lead to uneven tire wear:

- Irregular tread wear. Tyres may wear faster on one side due to incorrect suspension geometry setting, which can occur due to worn bushes.

- Steering problems

Damaged bushings can affect the steering system:

- Play in the steering system. The steering system may be less precise and the vehicle may respond slowly to steering wheel movements.

- Steering wheel vibrations. Vibrations that transfer to the steering wheel may be a sign of problems with the suspension bushings.

How to check if suspension bushes need replacing?

Damaged suspension bushing

If you notice one or more of the above-mentioned symptoms while driving, it is worth performing diagnostics on these elements.

- Visual inspection

The first and probably most effective step in diagnosing damaged bushings is a thorough visual inspection. This requires lifting the vehicle and assessing the condition of the bushings for:

Example of a stepped bushing

- Cracks and delamination. Visible cracks in the rubber parts of the bushings are a clear sign of wear.

- Deformation. Deformed bushings may not function properly, even though there is no externally visible damage such as scratches or cracks.

- Displacements. Bushes that are not seated correctly or appear to be shifted may need replacing. It may be that the bush connection to the wishbone is not correct and, despite no other damage, the bush needs replacing. In this case, it is worth checking the socket in the wishbone for damage and its diameter, as it may have been damaged, for example, when replacing stepped bushes.

- Suspension play tests

The next step is to check the suspension play. This can be done manually by moving individual suspension elements, such as control arms or anti-roll bars.

- Road test

The road test allows you to evaluate the vehicle’s driving behaviour:

- Reactions to inequality. Observe how the vehicle reacts to bumps in the road. Unusual sounds or instability may indicate bushing problems.

- Behaviour during cornering. The vehicle should hold the road securely when cornering. Stability problems may be the result of worn bushings.

- Suspension geometry measurement

Measuring suspension geometry can help identify problems resulting from damaged bushings:

- Taper (positive or negative) and camber angle. Deviations from the nominal values may indicate problems with the bushings.

Replacing the suspension bushings

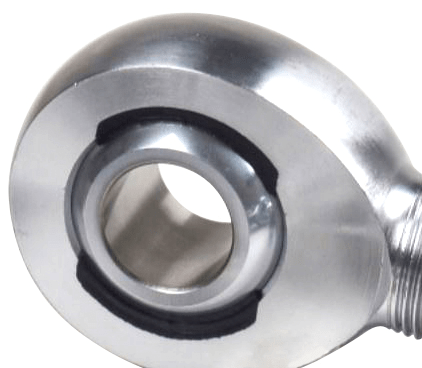

3-piece polyurethane bushing

Once it is confirmed that the suspension bushes are damaged, they must be replaced. This process, depending on the type of bush and its location, can be more or less complicated, and sometimes requires specialist tools or dismantling a significant part of the suspension elements. Tools that make replacing bushes easier are pullers, which allow the bushes to be replaced without dismantling the wishbones, so that the replacement can be carried out by one person and, additionally, with a significant saving of time.

In the case of polyurethane bushes, additional tools are usually not required to press them in. They usually consist of several elements that must be installed in the appropriate manner and order, paying attention to the necessary lubrication of points that are subject to displacement during suspension operation.

Manual bushing pullers

It should be remembered that suspension elements are an important element influencing driving safety. Their replacement is often a small cost, and the benefits of an efficiently functioning suspension system are immeasurably greater. Especially before the holiday season, when car journeys are often long and in difficult terrain, it is worth performing diagnostics and possible repairs. In the case of multi-link suspension, when only part of the bushing is damaged, it is worth performing a full service of the damping elements at once, because often the remaining elements (still functional) are very strained and may be damaged in the near future, exposing the car user to another visit to the workshop, which increases costs. In such a situation, it is good to use a bushing set, which contains all the elements necessary for servicing the suspension.

Example set of suspension bushes