Methods of decontamination and disinfection of vehicles at times of increased epidemic risk.

We have known for a long time that our well-being and, consequently, our motor skills, are strongly influenced by the appropriate thermal comfort and the quality of the air we breathe. In the current situation, the decontamination and disinfection of air conditioning systems and the vehicle itself does have additional importance, as they can directly affect our health.

Hazards related to the air conditioning system

As we already know, the air conditioning system is not maintenance-free, the system itself and the ducts must be regularly cleaned and disinfected. We frequently do not realize the serious consequences of poor (or lack of) maintenance, and we only become aware of them when we feel the unpleasant smell coming from the air vents, or in extreme cases directly from the interior of the car. This is due to the growth of mould, bacteria and fungi on the elements of the system. The most common place where such a cluster of microorganisms is formed is the evaporator, which absorbs heat from the interior of the vehicle and offers ideal conditions for the development of these organisms as it is located deep under the dashboard. A dirty evaporator generates an unpleasant smell, and the air flowing through carries it, along with harmful microorganisms, into the interior of the vehicle, which results in discomfort during travel and may cause various diseases. The most common risks associated with contaminated air conditioning systems are: allergies, respiratory tract inflammation, viruses (staphylococcus), bronchial asthma, tularemia or Legionella bacteria, which can even lead to a disease called legionellosis – and, as a consequence, acute pneumonia and death. At the present time, the air-conditioning system can of course become the area for the transmission of the coronavirus just as well as the interior of a vehicle, whether private or, for example, a public bus. Preliminary studies show that COVID-19 can survive up to 80 hours on different surfaces. Particularly vulnerable are people with reduced immunity – elderly or with coexisting diseases. The best preventive measure against exposure to disease is to maintain the air conditioning system and the interior in good condition and to keep it clean.

Decontamination and disinfection methods

So far, it has been recommended to disinfect vehicles at least once a year, preferably during A/C system service. Now, however, it is recommended and necessary to disinfect more frequently, e.g. every time you visit the repair shop or contact outsiders. The maintenance of vehicles operated by public transport, medical services or other uniformed services such as ambulances, fire trucks is also important. Which of the existing air conditioning disinfection methods will work best? I’ve decided to focus on the 3 that have been used for a long time: Ozoning – by means of ozone generating devices, “ultrasonic” method – creating a mist of disinfectant liquid by means of a special device, chemical – spraying or application of disinfectants on the interior of the vehicle.

Ozoning. The advantage of the first of these methods is that after purchasing the ozone generating device, there is no need to purchase additional chemicals during its service life. Ozone, or “active oxygen”, is a gas that can get into even the most difficult to reach places inside the vehicle and air conditioning system. Ozone has strong disinfectant properties, stronger than chlorine. The disinfection process itself is very easy and does not take much time.

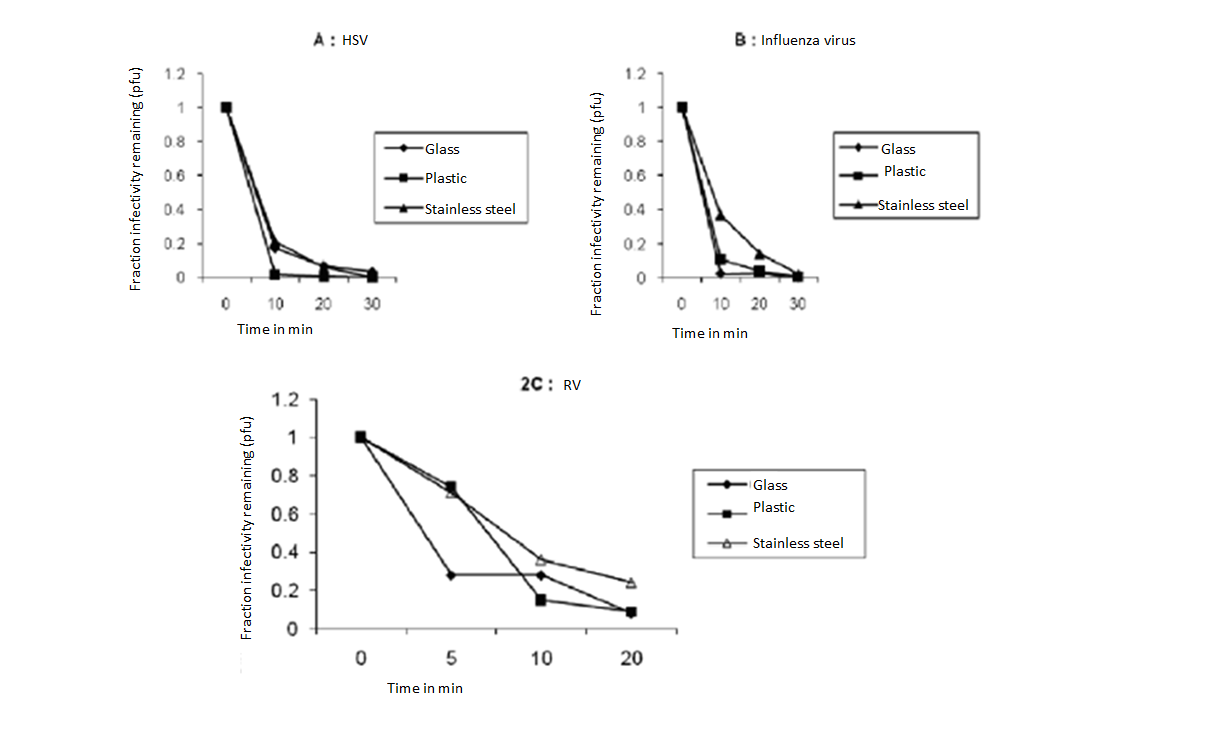

Many questions arose about the very effectiveness of ozone in the fight against microorganisms and viruses in particular. No studies have been carried out to date regarding the COVID-19 coronavirus itself, which causes SARS-CoV-2. However, the destructive effect of ozone has already been scientifically proven and tested for other viruses in the RNA family and for the enveloped viruses such as herpes (HSV), yellow fever (YFV), polio (PV), influenza, H3N2 influenza, rotavirus (RV) as well as the M-Cov belonging to the group of mouse coronaviruses

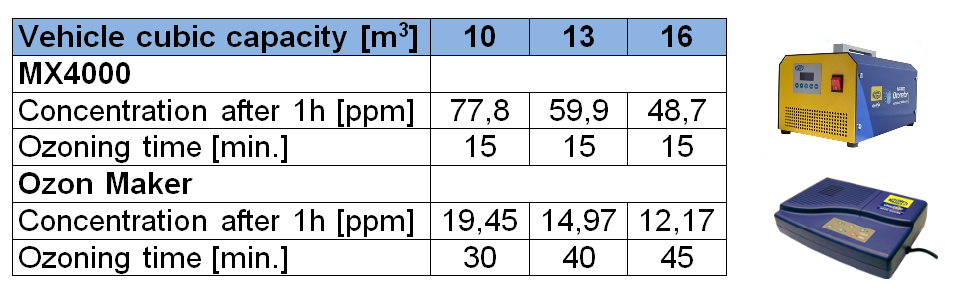

Although the exact mechanism has not been recognized, it is assumed that the strong oxidising properties of ozone damage the macromolecules, including the virus membrane, protein envelope, nucleic acids and RNA itself. As we can see in Chart 1, almost total (about 96%) deactivation at a concentration of 10 ppm takes place within about 20 minutes. In other studies, the deactivation of microorganisms has already taken place at a concentration of about 1 ppm and a time of 80 minutes. There are many devices on the market based usually on two technologies – ozone plates or ozone cells, the durability, quality and the need for regular cleaning of the former causes that a solid and recommended solution are ozone generators based on cells (ozone tubes). The advantage of this solution is also the possibility to connect the tube and apply the ozone stream locally to a given place, e.g. evaporator. Also the life span of the cell itself is longer than that of the plate and ranges from 5000 to 8000 h. An important value to pay attention to is the capacity of the device, usually expressed in mg or g per h – must be sufficient to suit the cubic capacity of the working rooms but also not too large. For a passenger vehicle it will be about 3-7 m3 , for a van (e.g. an ambulance) from 10 to 16 m3 and for a bus – in the range of tens of m3. Such designs are, among others, Magneti Marelli “Ozone Makers” producing 1000 mg of ozone per hour or MX 4000 with a capacity of 4000 mg/h. The recommended working concentration should be in the range of 1-5 ppm. It must be remembered that ozone is also very dangerous and the acceptable dose for humans for 8-hour exposure is 0.01 ppm and the concentration of 10-15 ppm is hazardous to human health. Taking into account also that the particle decay period is about 20-30 minutes, after each treatment, room ventilation is recommended – at least 30 minutes. The higher the temperature, the faster the particles decay, therefore the recommended working environment is no more than 25°C. The higher the temperature, the faster the particles decay, which will not allow to obtain the correct ozone concentration. An example of the theoretical range of concentrations of ozone generators is shown in Fig. 1.

Ozone concentration

Average cubic capacity of a typical ambulance is 10-16 m3 (Ford Transit, Mercedes Sprinter). Using Magneti Marelli ozone generators: MX4000 with a capacity of 4000 mg/h or Ozon Maker with a capacity of 1000 mg/h, the following conditions must be taken into account:

“Ultrasonic” method. The second method used for the disinfection of air-conditioning systems and the interior consists in dispersing a special liquid in the cabin of the vehicle by means of a dedicated device, which is designed to kill the microorganisms present in the system. One such device is the BACTOBAN ultrasonic nebuliser. The principle of operation of BACTOBAN, consists in introducing a disinfectant solution on the surface of a piezoelectric crystal, which by vibrating at a very high frequency (ultrasonic frequency – hence the name of the disinfection method as well as the device itself), creates a mist floating over the ultrasonic transducer. This mist is directed to the outlet of the device by a fan. It is then absorbed by the air circulating in a closed circuit in the cabin and thus enters all the places that require decontamination (especially the evaporator o the AC system), eliminating germs and unpleasant odours.

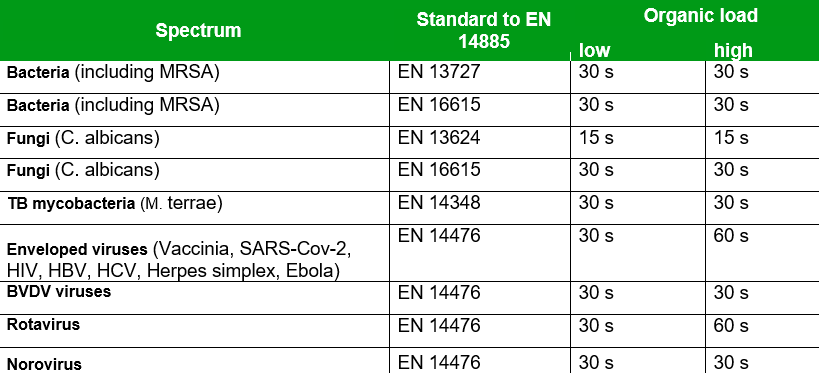

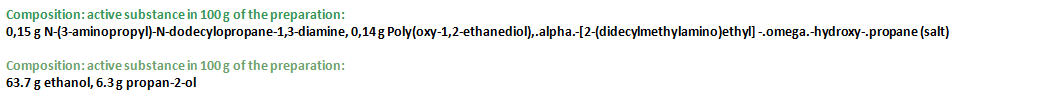

The important issue is the fluid we use. On the market, we can find a multitude of dedicated products with ethanol or isopropanol content at the level of 5-30% (much less than 70% recommended by the WHO), however, there is no certainty about the virucidal effectiveness of such products, unless the fluid meets the EN14476 standard and preferably also the EN16777 standard. Importantly, compliance with the standard and virucidal properties (enveloped viruses like COVID-19) also show fluids with low ethanol content but containing other substances with a broad spectrum of biocidal activity such as chlorides or amines. These products seem to be the best choice for ultrasonic devices, they guarantee dilution with the right amount of water that serves as a carrier. They should not generate problems with the sensors inside the device, which may block operation due to too high a concentration of non-conductive alcohol.

The method works well in regular maintenance as well as in specific cases where a high concentration of odour can already be detected when the A/C system is switched on. For large amounts of contamination on the evaporator, ozoning may no longer be effective enough and only a procedure using dedicated disinfectant fluids can bring the expected results. We just need to remember that the mist must reach any place we want to disinfect. The disadvantage of this solution are the required purchases of fluids.

Disinfection with chemical agents. At the moment, perhaps the most widespread and available. Chemical preparations for both disinfecting the air conditioning and surfaces are available in the form of sprays for direct application or atomisation, as well as concentrates, to be diluted with water, which can then be used in atomisers or applied directly. Here too, preparations can be divided into those based on alcohols (isopropanol, ethanol – we have to remember that their concentration must be quite high about 60-70% according to WHO for virucidal properties) or those based on chlorides and amines or other biocidal substances. In the case of preparations non-compliant with the standards, their effect may be limited, e.g. only to bacteria and fungi or not strong enough.

In conclusion, we have to choose the best disinfection method for our needs. In order to be effective, it must meet certain tested conditions or standards for application.

Endnotes

- Inactivation of Surface Viruses by Gaseous Ozone Chunchieh Tseng and Chihshan Li Journal of Environmental Health Vol. 70, No. 10 (June 2008), pp. 56-63 (8 pages)

- Development of a Practical Method for Using Ozone Gas as a Virus Decontaminating Agent May 2009

- Ozone therapy: A clinical review A. M. Elvis and J. S. Ekta J Nat Sci Biol Med. 2011 Jan-Jun; 2(1): 66–70

- Ozone Disinfection of SARS-Contaiminated Areas Kenneth K. K. LAM B.Sc. (Hons), M. Phil. Enviro Labs Limited, 611 Hong Leong Plaza, 33 Lok Yip Road, Fanling, HONG KONG

- Trzcińska A. Badanie aktywności wirusobójczej środków dezynfekcyjnych stosowanych w obszarze medycznym.

- Zakażenia XXI wieku 2019;2(5):241–248. 10.31350/zakażenia/2019/5/Z2019037