The only connection with the road

The general opinion of the automotive experts from a safety point of view is that the brake, steering and chassis must always be in a roadworthy condition, because with their help we can avoid emergencies and accidents.

The lack of raw materials and other economic recessions have not reduced the price of passenger and truck tyres either, so we tend to save on this component. In this technical overview, we would like to draw attention to this element, which is probably the most important component of the chassis.

The vehicle’s tyre may not seem very important at first, but it’s worth considering what depends on it while driving.

It is not an exaggeration to say that almost all the developments of manufacturers and suppliers (electronics, drive, power source, braking system, etc.) can lose their meaning in a given situation if the tyre, which ensures the connection with the road, does not function properly. It is easy to see that no matter how much acceleration and braking power we have available due to the construction, we can only use as much of it as our tyre allows – not mentioning turning.

Birth of tyre

In the period before the automobile and at its dawn, wheels made of wood and metal reinforcements were typically used. However, as speed increased, this design proved to be too rigid and fragile.

In 1839, Charles Goodyear invented the method of vulcanization, which in short means that during the process, under the influence of high heat with the intervention of sulfur, cross-links are created between the chain molecules of rubber. Thanks to these forms of bonding, the rubber is able to take on both flexible and solid properties – originally, the strength was missing from their rubber (nowadays, many other raw materials are also used, but this will be also a topic later).

In 1888 Dunlop installed a water-filled, then air-filled hose pipe for the first time on a children’s bicycle, replacing the metal wheel. The automotive industry quickly embraced the technology and has continued to develop it.

Construction of today’s tyre

It looks extremely simple from the outside, but in reality the product is characterized by a relatively delicate production process and many components.

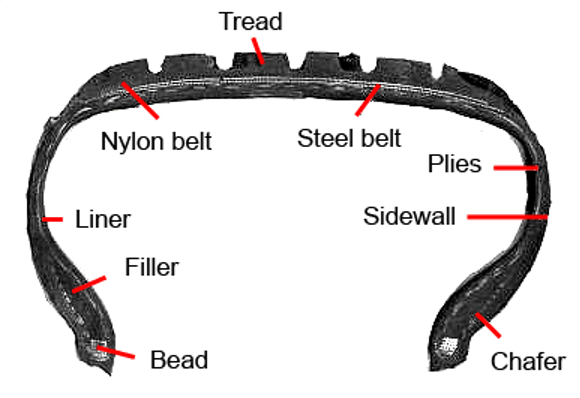

Components of a tyre – cross section (source: wikipedia.org)

Here we list the most important elements and their functions.

Tread: A patterned surface that ensures contact with the asphalt (Tread). This is the part where we can get the most information about the tyre at a glance: season, level of wear, and even the condition of the chassis can be seen from the wear pattern.

The tread must provide traction even if foreign matter gets between the road and the tyre – for example rainwater. This is when the design of the pattern becomes important, with which the manufacturers try to squeeze as much water as possible from under the tyre during one turn of the wheel, so that the phenomenon of aquaplaning, i.e. sliding on water, occurs as late as possible.

Winter tyres have a similar task, but the problem must be approached from a different angle. The wheel can’t push the snow out from under it, and the tyre-snow connection doesn’t really provide good traction.

But snow-snow relationship can. Therefore, with the pattern of winter tyres, tread can squeeze as much snow as possible from the road between the patterns, and thanks to this, the rubber gains extra grip.

That is why we can find many more, more detailed pattern elements on winter tyres, even in the transverse direction, as well as strong lamellation. And this is not the only difference between winter and summer tyres (e.g. the typically softer winter compound, which usually ages sooner), but this is the most important point in terms of tread.

The tread of an all-season tyre is a mixture of these characteristics (usually the middle part of the surface resembles winter, and the edge resembles summer).

Winter tyres are designed based on completely different principles (source: pixabay.com)

In the past, it was typical for passenger cars, but today we can see “run-down” tyres only on trucks, which have already worn out the original tread, and after cleaning the structure of the original residue, it gets a new tread. This industry, of course, was created to save costs.

Pattern grooves: There is a gap in the tread pattern of the tyre, which according to official regulations can be at least 1.6 mm. From the service point of view, it is a general recommendation to change the tyres on the vehicle at least at 3 mm.

Sample element: the sample elements are located in the running tyre, positive sample part.

Liner: Ensures the tyre’s breathability and prevents moisture and steam from entering the tyre.

Steel belts: They ensure the stability of the running surface. Laterally, the belt must be rigid to resist sliding, and radially flexible to absorb obstacles.

Carcass: The tyre’s load-bearing frame. Together with the belt inserts and the frame part between the rim.

Nylon belt: in the case of a radial tyre, an optional intermediate insert between the tread and the belt, the purpose of which is to limit damage to the belt.

Bead: The coiled steel wire hoop embedded in rubber. This clamps the tyre onto the strap, it can withstand a force of up to 1800 kg without the risk of tearing.

Rim protector: The tyre comes into contact with the strap through the rim protector’s surface. You cannot allow the mantle to slip on the strap, and it must withstand the friction caused by slipping mechanically.

Valve: Attached to the rim (tubeless) or vulcanized into the tube, it allows you to inflate the tyre with air and check the air pressure.

Valve protection cap: Protects the valve structure from dirt and moisture. In order to seal the valve, it is essential.

The raw material of the tyre

What we simply call rubber in this part is also consists of many different components. Natural rubber is still in use today, but in addition to that, at least in proportion, we find synthetic polymers, the types of which we could write a separate article about (e.g. chloroprene, as a polymer neoprene or polyisoprene, NBR, i.e. nitrile-butadiene rubber, etc.)

In addition to the main raw material, we also find fillers, such as carbon black, which gives the color of the tyre, silicon dioxide, which binds the sulfur for vulcanization, limestone, etc.

Rubber plantation along the road (source: pixabay.com)

The fillers are not primarily responsible for the color, but to extend the life of the tyre and make it more resistant to environmental influences.

The third group is softeners. These oils and resins make the tyre flexible and improve the adhesion of the material. Oils also increase the tyre’s slip resistance. That is why more oil is used in winter tyres than in summer tyres; softeners prevent the rubber from becoming harder and stiffer at low temperatures.

Modern developments

In the last 20-30 years, there have been changes not only in the material quality, but also in the structure. Pressure-monitoring TPMS sensors are widespread within the EU and in many other countries, and puncture-resistant tyres are now almost usual in higher passenger car categories.

Due to the electromobility, the manufacturers were forced to find alternative solutions both in terms of rolling resistance and load capacity due to the increased mass load. Today, every major company has at least one tyre family that is made specifically for battery electric cars – this portfolio will gain more and more space in the future.

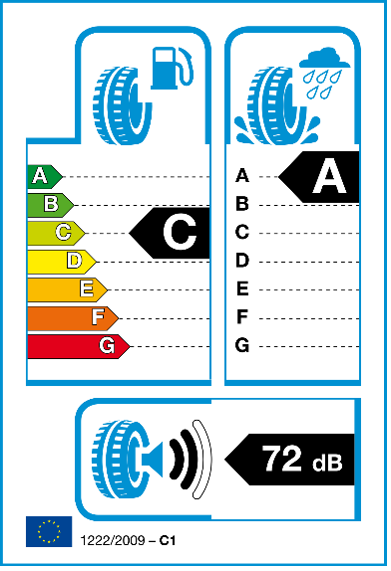

EU certification

The purpose of the EU regulation (1222/2009), which entered into force in 2012 is to improve the safety and efficiency of vehicles in road traffic, and to reduce the environmental impact of tyres.

In recent years, customers’ demand for information on the actual performance characteristics of tyres has increased. The EU regulation aims to help with this in terms of three important parameters.

EU tyre label (source: wikipedia.org)

According to the regulation, from of November 1 2012 all passenger car, SUV, light commercial vehicle and truck tyres manufactured after July 1, 2012 must have the data indicated on them (or placed at the point of sale) in order to provide information before purchase. In addition, the tyre label data must be indicated on the invoice received at the time of purchase. The label provides data on 3 characteristics: fuel efficiency (rolling resistance), braking on wet roads, rolling noise.