Keeping your car air conditioning system in full working order – expert advice from NRF

Summer is the time when the car air conditioning system works the hardest, and any malfunctions and inefficiencies become particularly troublesome. Moreover, in the event of a malfunction, we will have to wait a long time for a place in a specialized workshop. NRF experts remind us of the simple steps that will guarantee trouble-free air conditioning operation during the hottest time of the year.

Checking activities include checking the correct operation of the system, all its functions and settings, evaluating performance and responsiveness. In addition, it is worth visually assessing the condition of individual system components that may have been damaged:

-

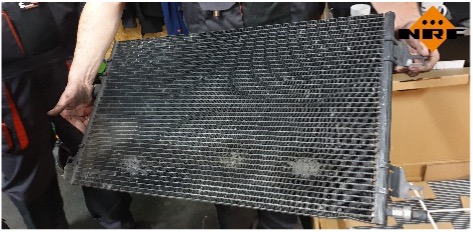

Photo 1 Contamination and damage to Condenser condenser – it is usually mounted just behind the front bumper of the vehicle, so it can easily be damaged. In addition, dust and other contaminants accumulate in the fins of the condenser, leading to deterioration of performance over time.

- Belt drive – pay attention to visible cavities in the belt grooves, fraying of its edges and the degree of tension.An additional symptom of wear and tear is squeaking of the belt during operation. Also take a look at the pulleys. Uneven belt tracking caused by a loose wheel or an immobilized guide pulley will not only shorten the life of the belt, but can also lead to a serious and sudden failure.

- Compressor – look for signs of possible leaks or oil leaks.

-

Photo 2 Contamination of the compressor pulley suggesting an oil leak. A/C lines, electrical connections and the like – look for visible signs of leaks or damage, as well as signs of corrosion.

If no abnormalities are detected, it is also worthwhile to conduct a functional test. It allows you to easily assess the actual efficiency of the air conditioning system, as it is not uncommon for the deterioration of efficiency to be spread out over time and not draw the attention of vehicle users.

The test itself is limited to a few simple steps:

- park the car in the shade

- open all doors and windows

- start the engine and keep the speed at 1500-2000 rpm

- turn on the air conditioning, set the minimum temperature and set the maximum air speed

- start the closed-air mode

- set the air supply to the face and leave only the middle air ducts open

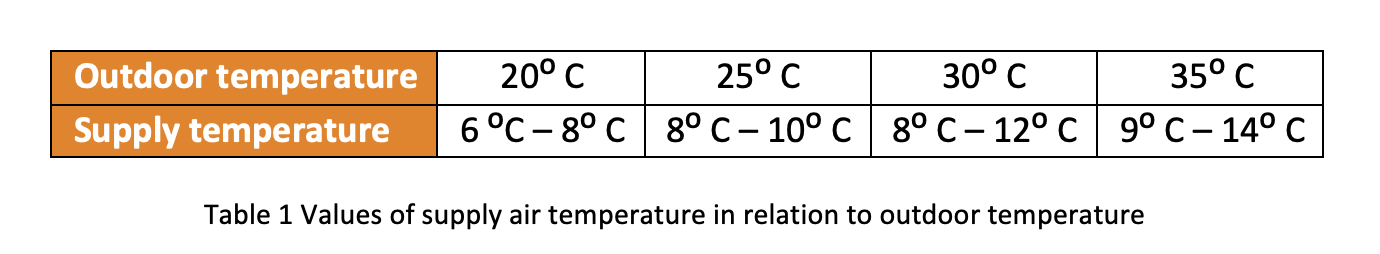

- after about 5 minutes, measure the air temperature at the vent outlet in the center of the dashboardThe temperature reading with a properly functioning system should roughly match the values in the table below:

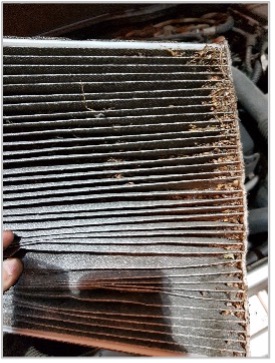

NRF experts recommend a visual and functional check of the air conditioning system at least once a year. The vehicle’s cabin filter should be changed with the same frequency. It is worth equipping yourself with an activated carbon filter – they provide better protection against contaminants and have a beneficial effect on the elimination of unpleasant odors.

The above activities do not require specialized knowledge or skills. Instead, they will allow you to catch possible faults before they lead to a serious breakdown. For example, a damaged compressor pulley can often be replaced with a new one and avoid costly replacement of the compressor itself.

NRF has a range of more than 300 different small parts dedicated to air conditioning systems, from the aforementioned pulleys to compressor clutches, coils, expansion valves, pressure sensors to pressure switches.

IMPORTANT: NRF recommends that any mechanical intervention in a vehicle’s A/C system related to its repair or replacement of components be performed by qualified mechanics at specialized workshops.

Air conditioning service requires the use of specialized equipment and qualified personnel. In addition to the checks described earlier, the actual amount of refrigerant in the system should be verified during the service because in some vehicles the air conditioning may appear to be functioning normally even with only 50% of the refrigerant present. This is particularly important not only from the point of view of cooling performance.

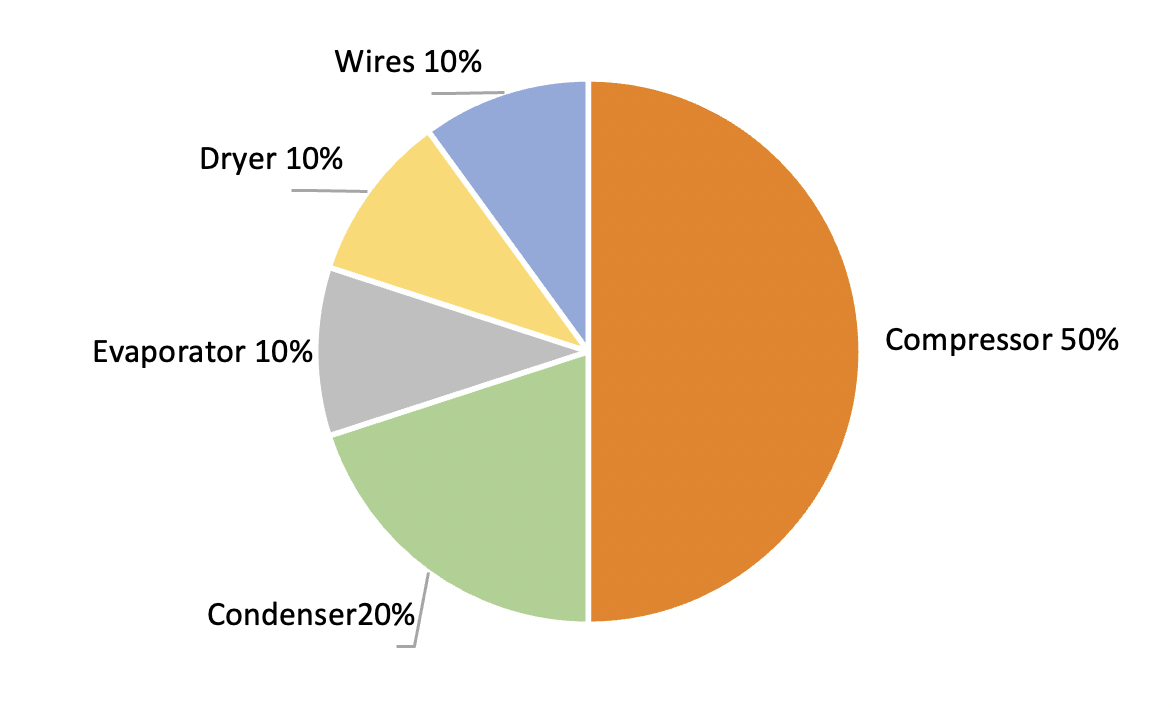

The refrigerant is also the medium that is responsible for circulating the oil in the system. As shown illustratively in the diagram, only about half of the oil volume is in the compressor. The remainder is distributed to other components and circulates with the liquid refrigerant as a homogeneous mixture while performing various functions, such as providing corrosion protection. Consequently, loss of refrigerant also means loss of oil flow and can lead to faster wear of parts and also to serious failure..

NRF recommends using only the highest quality oils designed for automotive air conditioning systems. The brand’s compressors are pre-filled with premium oil to ensure long and trouble-free operation. The company’s portfolio includes 1,000 compressors for all types of vehicles.

Another point when performing air conditioning service is to verify the condition of the filter-drier and replace it if necessary. Moisture inside the system is its biggest enemy. It causes corrosion, negatively affects the lubricating properties of the oil, degrades performance and can directly cause failure. In extreme cases, water can freeze in the expansion valve, causing blockage of refrigerant and oil flow. The vacuum generated in the system during servicing not only verifies its tightness, but also allows the system to evacuate residual water. Although replacing the dehumidifier may seem like an unnecessary cost especially since most of them are now an integral part of the condenser, it may turn out to be only a fraction of the value of the repair in the event of a serious failure that could have been easily avoided. In other words, it’s an apparent savings.

Since dryers are extremely sensitive to the way they are transported and stored because of the possibility of moisture getting inside them and prematurely saturating them, NRF has developed its own standards related to this. These apply to both condensers, of which the company currently offers more than 900, the dehumidifiers themselves, i.e. another 280 items, and the previously mentioned compressors. At the end of the production process, A/C parts are subjected to vacuum and then filled with inert gas (nitrogen or helium). The unsealing of such a component occurs only just before it is installed in the workshop. This is accompanied by a characteristic hissing sound.

Since dryers are extremely sensitive to the way they are transported and stored because of the possibility of moisture getting inside them and prematurely saturating them, NRF has developed its own standards related to this. These apply to both condensers, of which the company currently offers more than 900, the dehumidifiers themselves, i.e. another 280 items, and the previously mentioned compressors. At the end of the production process, A/C parts are subjected to vacuum and then filled with inert gas (nitrogen or helium). The unsealing of such a component occurs only just before it is installed in the workshop. This is accompanied by a characteristic hissing sound.

In view of the above, NRF experts recommend that a full air conditioning service should be performed no less often than once every 2 years. In addition, remember to use air conditioning in the vehicle regardless of the season and weather conditions. This will avoid a very unfavorable situation, when the system, which has been stagnant for several colder months, with the rise in temperature is suddenly forced to work at full load and maximum efficiency. What’s more, minor inconveniences and the first symptoms of impending defects can be caught even before the period when air conditioning is most needed.

In view of the above, NRF experts recommend that a full air conditioning service should be performed no less often than once every 2 years. In addition, remember to use air conditioning in the vehicle regardless of the season and weather conditions. This will avoid a very unfavorable situation, when the system, which has been stagnant for several colder months, with the rise in temperature is suddenly forced to work at full load and maximum efficiency. What’s more, minor inconveniences and the first symptoms of impending defects can be caught even before the period when air conditioning is most needed.

and eliminated in advance.

We hope that the advice we have provided will be useful to you. A set of basic checks is the best way to verify the condition of the air conditioning system in your vehicle,

and properly and regularly performed service guarantees long and trouble-free operation. It is worth giving it due attention, and if any defects are detected, bet on reputable replacement parts.

Thank you for your trust.

NRF’s team of air conditioning system experts.