Even lighter, even more variable for on- and off-road: BPW renews Airlight II trailer running gears

- BPW renews successful running gear for the 9-ton segment

- Weight advantages of up to 60 kilograms in the 9-ton off-road range

- The BPW effect: savings of up to 200 kilograms CO2 per year

- Intelligent modules with digital DNA enable precise vehicle design

- Patent-pending laser technology developed especially for 9-ton running gears

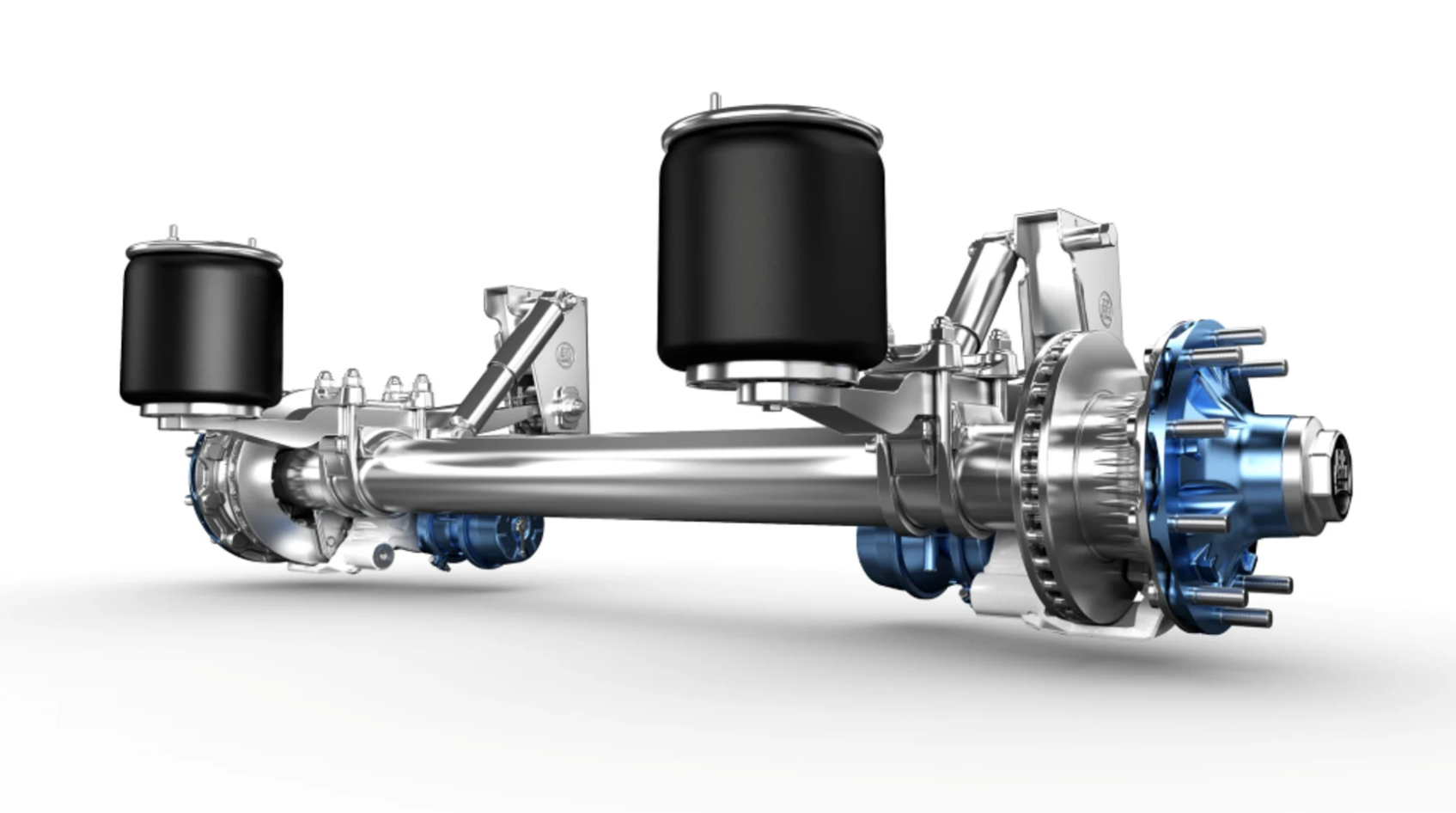

Weight savings of up to 60 kilograms are a sensation in the trailer industry. The engineers at BPW Bergische Achsen KG have achieved this with the new generation of the Airlight II running gear kit. Thanks to digital DNA, laser technology and intelligent modules, the kit now covers an even wider range of applications – both on the motorway and off the beaten track.

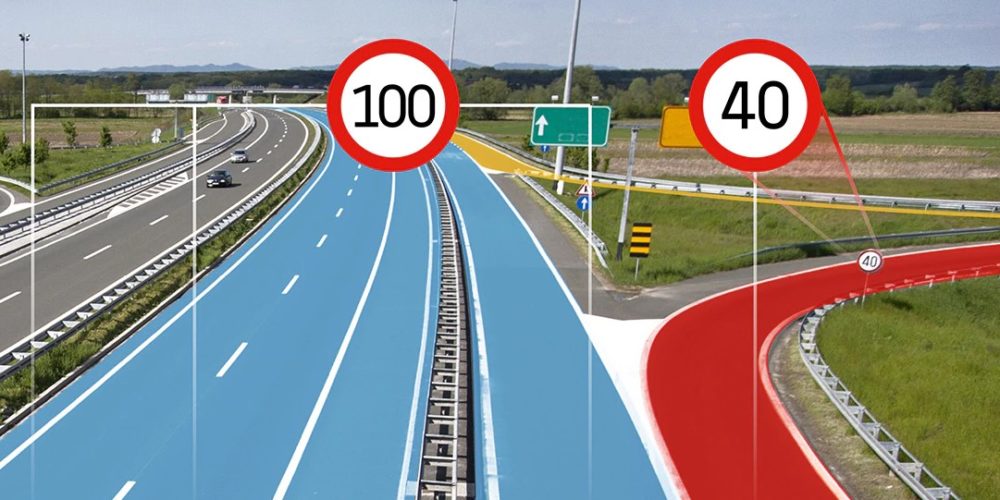

Whether basalt chippings or coronavirus vaccines, cereal or heating oil, no two transported goods are the same. This is why drawbar trailer running gears are precisely designed for their intended use. As a specialist in trailer technologies, BPW enables vehicle manufacturers to build highly specialised and at the same time outstandingly economical drawbar trailers. BPW now promises even more variety and economy with the new generation of the Airlight II running gear kit – one of the best-selling trailer running gears in Europe.

The generation change is being introduced in the Airlight II kit for the 9-ton axle load range with clamped spring seat arrangements, as they are typically used for tipper, tank and silo vehicles or also for special box bodies. For the first time, all components of Airlight II are also based on the “digitial twin” principle. The digital DNA enables vehicle manufacturers to determine the perfect running gear configuration for highly specialised applications online from countless options – and to order it at the click of a mouse.

A new feature is the combination of the clamped spring seat arrangement of the Airlight II air suspension in conjunction with a round axle beam. This is made possible by the patent-pending laser processing of the contact surfaces in the spring seat arrangement. This extremely robust mounting, combined with a round axle beam used in both 9-ton on-road and off-road applications, enables off-road weight savings of up to 60 kilograms compared to previous versions. “BPW sets standards in this combination. We combine unshakeable sturdiness with a new lightness,” said Denis Wierwille, Trailer Solutions & Mobility Services Product Manager at BPW.

In on-road weight-sensitive transport, the two lightweight design options LightTube trailing arm and aluminium hub can still be used. In this way, a module weight of less than 370 kilograms can be achieved, which is the benchmark in the range of running gears for 9-ton axle loads.

BPW already heralded the revolution in running gear design in 2019 with the ECO Air running gear kit. This kit covers standard running gears for the 9-ton segment. The laser process celebrated its premiere with ECO Air and has since proven itself hundreds of thousands of times over.