Alternators: What are their typical faults and how can they be fixed? – DENSO has issued a technical troubleshooting guide

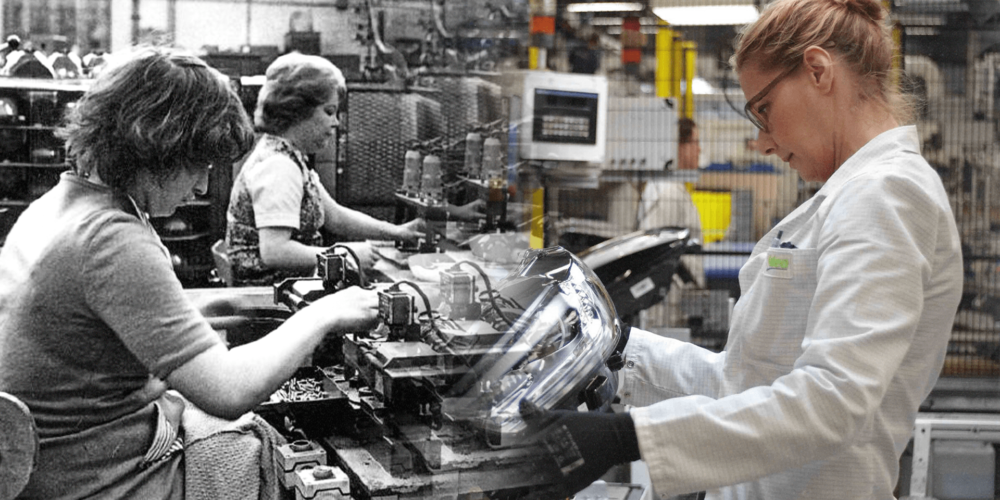

Today, the Japanese company DENSO has a 25% global market share of factory components for rotating electrical components. Replacement starters and generators provided by DENSO Aftermarket provide high efficiency and performance as well as outstanding wear resistance.

Its operating principle is simple: it is driven by the engine via an auxiliary belt, which converts mechanical energy into electrical energy – while driving, the battery is constantly recharged by the generator. So generators actually produce alternating voltage according to the laws of electromagnetic induction – motion induction. The creation of the generator can be attributed to the British physicist and chemist Michael Faraday, who created the first generator in 1831.

The voltage produced by the generator is an alternating voltage that can be characterized by peak value, instantaneous value and frequency. The peak value: the maximum value of the voltage, the instantaneous value is the instantaneous value of the voltage, and the frequency is the number of vibrations per second.

Below you can read the troubleshooting tips from DENSO’s manual.

The battery must be fully charged (12.6 volts or more), the battery cables must be intact, clean and free of corrosion.

We check the voltage drops on the + and – sides.

Measure the resistance on the + and – side with a multimeter. If the voltage drop test reads more than 0.2V on the positive side (output circuit), it indicates that there is excessive resistance somewhere on the positive side.

Check for broken, loose or missing ground points/harnesses between engine and chassis.

If you don’t find less than 0.2 volts during the test, continue testing with electrical tests.

You can measure the alternator output current by running the engine at 2000 rpm when the output current reaches 10 amperes at the alternator output (B+). Measure the output current in this way, then set the headlights to high beam, turn up the heating power also with an engine range of 2000 rpm and measure the output current again. The measured value must match or exceed the standard values given by the relevant vehicle manufacturer.

In addition, it is necessary to check the fuses – a broken fuse means a circuit problem.

Check the condition and tension of the drive belt belonging to the generator – if it is too loose, the generator will not charge at all, if it is too tight, internal bearing damage may develop inside the generator.

The operation of the generator can also be checked using a portable oscilloscope.

If we need an aftermarket generator, we need to pay attention to the following things:

- The replacement alternator does not have to look like the original unit, but must provide equivalent performance and have the same pulley specifications and interface dimensions.

- Choose the offer with the longest possible life, strive for maintenance-free. An alternator with a lower current output is not allowed for a vehicle that requires a higher output alternator.

- Other important features are the suitability of the type of regulator, the type, diameter and number of ribs of the pulley, as well as the dimensions of the mounting interface.

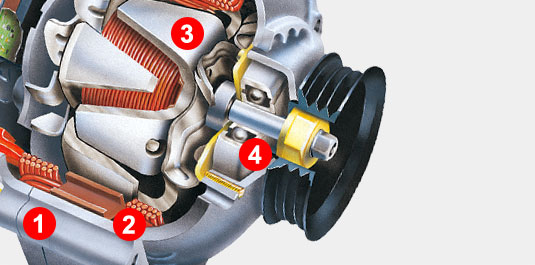

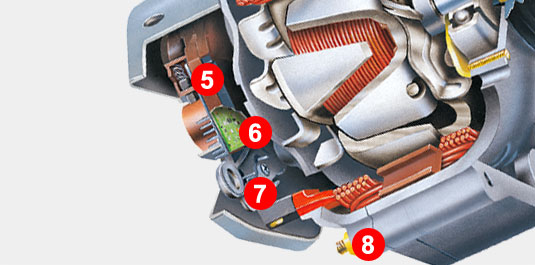

The parts of the generator can be seen in the figures below:

Source: www.densoautoparts.com

- Housing: Threaded according to OE standards and checked for heat loss or corrosion.

- Stator: The insulation is tested to 600 volts.

- Rotor: Power and insulation tested at 600 volts.

- Bearing: Tested according to OE standards.

- Slip ring: Reworked to an average of 8 microns.

- Voltage Regulator: 100% voltage tested to OE standards.

- Rectifier: Power is tested at 300V.

- Hardware

Alternators: What can go wrong and how to fix it – Garage Wire