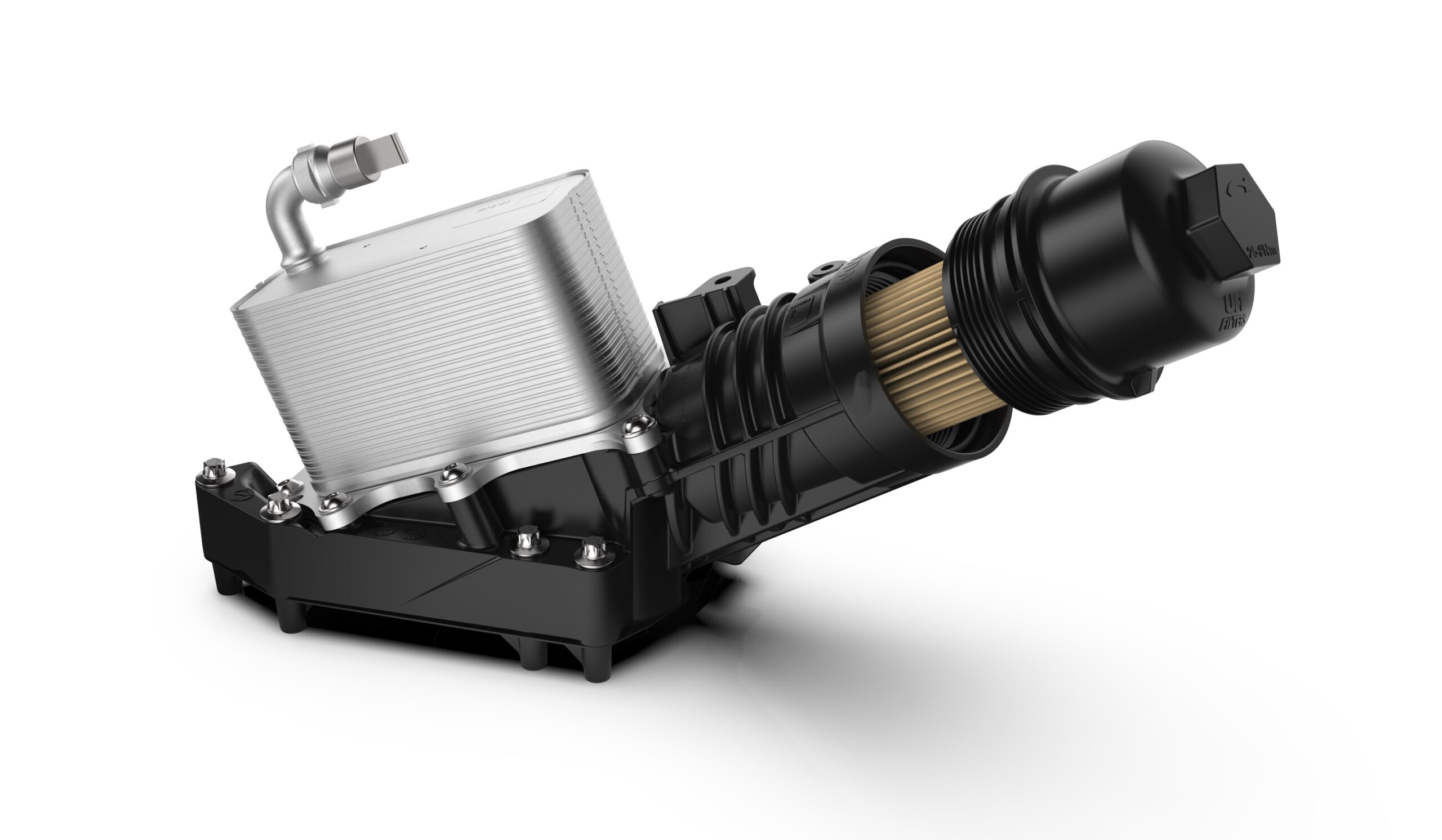

UFI Filters oil module for BMW second generation 6-cylinder engines

- Complete oil filter module for new 3.0 litre B57 6-cylinder diesel engines

- Plastic filter body reinforced with fibreglass and UFI Filters-made heat exchanger

- Exclusive product produced entirely by UFI at its European industrial sites

UFI Filters, a leader in filtration and thermal management, is once again confirmed as a trusted partner of BMW. The German car maker has chosen the complete oil filter module made by UFI for the second generation of 3.0 litre B57 6-cylinder diesel engine.

While UFI has been developing products for diesel fuel filtration in BMW cars for many years, this supply contract serves to further consolidate the company’s key partnership with the Bavarian premium vehicle manufacturer. The agreement is testament to the high technology and reliability of UFI oil filters, which are becoming more widely used by vehicle manufacturers.

The new project supplements UFI Filters’ supply – as Original Equipment – of the oil filter module for petrol B58 engines and diesel B57 first generation engines. UFI Filters extends its offer to BMW, equipping all the 6-cylinder models of the German group.

The oil module supplied to BMW is entirely produced by UFI Filters, with the central body manufactured at the Ostrava industrial site in the Czech Republic and the heat exchanger made at the Opole plant in Poland. The materials used are technologically advanced; the filter body is entirely made from plastic, reinforced with fibreglass.

The plastic structure ensures significant weight savings over similar modules made from metal (-35% approximately), resulting in reduced fuel consumption and a drop in pollutant emissions. The use of fibreglass considerably strengthens the structure of the body. This allows the filter to operate under pressures of up to 30 bar l, just like similar structures using die-cast metal.

The oil module filter element supplied to BMW uses a filter media which maximises the filter surface area and minimises pressure drops. This technology benefits from an innovative ultrasound bonding method, resulting in a dramatically improved seal, even under the most demanding operating conditions and without the use of metal. The filter efficiency of 50% @13µ is fully in line with Euro 6 requirements. The filter media is 100% recyclable – a further testament to the company’s dedication to reduce the environmental impact of its products.

The oil module supplied to BMW comes complete with a heat exchanger and a series of valves developed and manufactured entirely by UFI Filters. Inside the body there is one anti drain valve and two bypass valves, one of which can also function as an anti drain valve. The bypass valve allows for optimal oil management and guarantees the highest performances even in cold start conditions.

Luca Betti, Business Unit Aftermarket Director for the UFI Filters Group, says: “We are delighted that once again BMW has placed its trust in the UFI Filters oil module. This is further confirmation of the continuing evolution of our filtration solutions. Accordingly, our Aftermarket customers will benefit from these range extensions and high value-added products, developed to the most stringent OEM standards. Sales of the cars equipped with our filter are expected to be high. Many of these will join corporate fleets and are therefore more likely to be maintained through independent service and repair workshops – an aspect that will make the UFI oil filter a key Aftermarket product.”

The oil module filter element developed for BMW is available for UFI Filters’ Aftermarket customers, both under the UFI and the Sofima brand (with their respective product codes, UFI 25.148.00 and S 5148 PE).