Premium Turbo replacement form Nissens

Forced induction engines have gained a strong foothold in all vehicle segments and made turbochargers an increasingly common replacement part. Choosing premium quality aftermarket spare parts technicians can ensure a first-class repair and the most optimal engine performance.

Genuine Nissens Quality

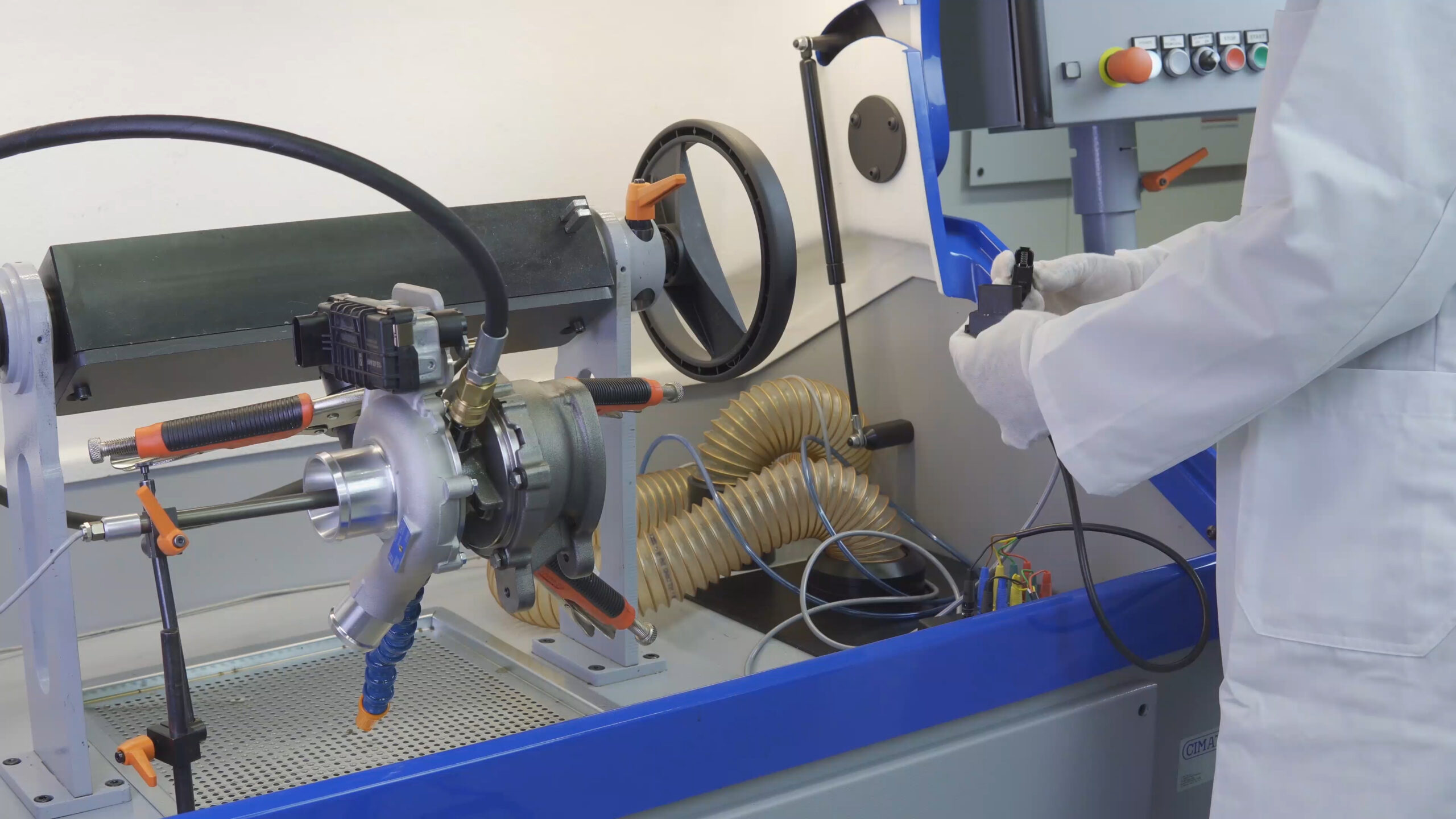

Nissens Automotive introduced turbos back in 2018. Expanding the Engine Efficiency & Emissions range has enabled the company to offer the independent aftermarket a premium replacement alternative. As a result, Nissens built a specific team and invested in the design and production facilities required to deliver on its commitment and develop a turbo offering underpinned by comprehensive internal and external validation and test procedures, independently verified by bodies such as TÜV.

Nissens Turbos reflect the high Genuine Nissens Quality standard known from other Nissens’ parts such as thermal management components. The turbos from Nissens are designed, manufactured, and tested to secure excellent engine performance, fuel economy, emissions standards, and durability, matching the engine’s lifespan.

Convenient Solution & Competitive Range

Alongside the range of premium-quality products, Nissens has added convenience for both the distributors and the workshops. All Nissens’ turbos are brand new units and do not require the return of the old part or are subject to any surcharge. In addition, they all are easy to install. The “First Fit” feature means all necessary installation parts, such as gaskets, stretch bolts, clips, prime oil, and comprehensive installation guides, are delivered in the box, making the fitting process straightforward.

The range of Nissens’ turbos consists of more than 270 part numbers covering 3,200 OE references that, in addition to passenger car and light van applications, also include 40+ truck turbo models. The range is under continuous development and increases the already high, over 50% EU car park coverage.

Covering the latest turbo technology

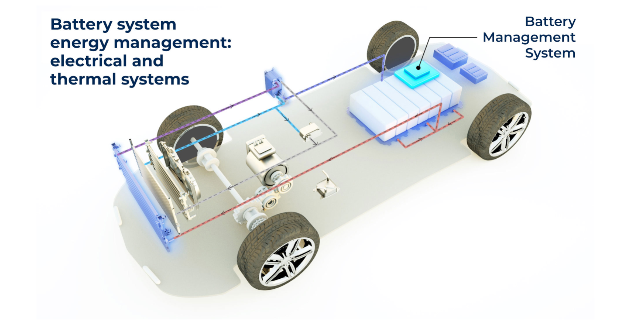

As the advanced engine designs in the premium vehicles segment apply electrically actuated turbos, the Nissens Turbo program also includes parts made with this advanced technology.

There are several benefits to electronically controlled turbos. Because voltage can provide precise signaling control, the electric-driven actuation provides a highly accurate, smooth, and fast control of the vane mechanism of a variable turbo. It enables the turbo to quickly and stably react to optimally match the given engine needs. In addition, electronics offer higher and more precise diagnostics capabilities.

Besides wastegate and variable turbos with pneumatic actuation, the company has recently developed a line of 25 turbos with electronic actuation dedicated to the newest Euro 5 and 6 engines. Several e-Actuator turbos in the Nissens range are equipped with OE-manufactured electric units from HELLA.

A Comprehensive Solution

The Nissens turbo offering falls within the company’s Engine Efficiency & Emissions product category, encompassing intercoolers, EGR solutions with valves, modules, and coolers. It also includes turbo oil feed pipes – a component that enables technicians to complete a thorough, first-time-right turbo replacement and proper lubrication of the new unit.

In addition to great products and depth of range, Nissens also supports aftermarket with comprehensive technical solutions essential for professional turbo installation, maintenance, and troubleshooting. For the major regions and languages, the company has established a turbo-dedicated hotline, the company’s top-notch e-learning, live learning, and technical marketing with stories and videos related to turbos are all available at www.nissens.com/experts